As a business owner, you understand the necessity of keeping your products within the correct conditions that must be maintained. So why not look into capitalising on the benefits that cold chain logistics solutions have to offer in particular asset tracking? Implementing specialised solutions for monitoring within the cold chain will allow you to track if set conditions have been maintained throughout. If conditions continually fluctuate this can impact product quality ultimately leading to waste and consequently orders needing to be re-fulfilled. In this blog post, we’ll take a deep dive into some of these benefits of cold chain logistics solutions in particular the use of asset tracking devices that form an integral part of any successful cold chain solution. So let's begin unpacking the value cold chain logistics solutions can add to your business.

Outline:

1. Introduction: What Is Cold Chain Logistics?

2. Benefits Of Cold Chain Logistics Solutions Such As Asset Tracking Devices For Businesses

3. Different Asset Tracking Devices for A Successful Cold Chain Solution

4. How To Implement A Robust Cold Chain Logistics System

5. Conclusion: Summary Of The Benefits of Investing In Cold Chain Logistics Solutions

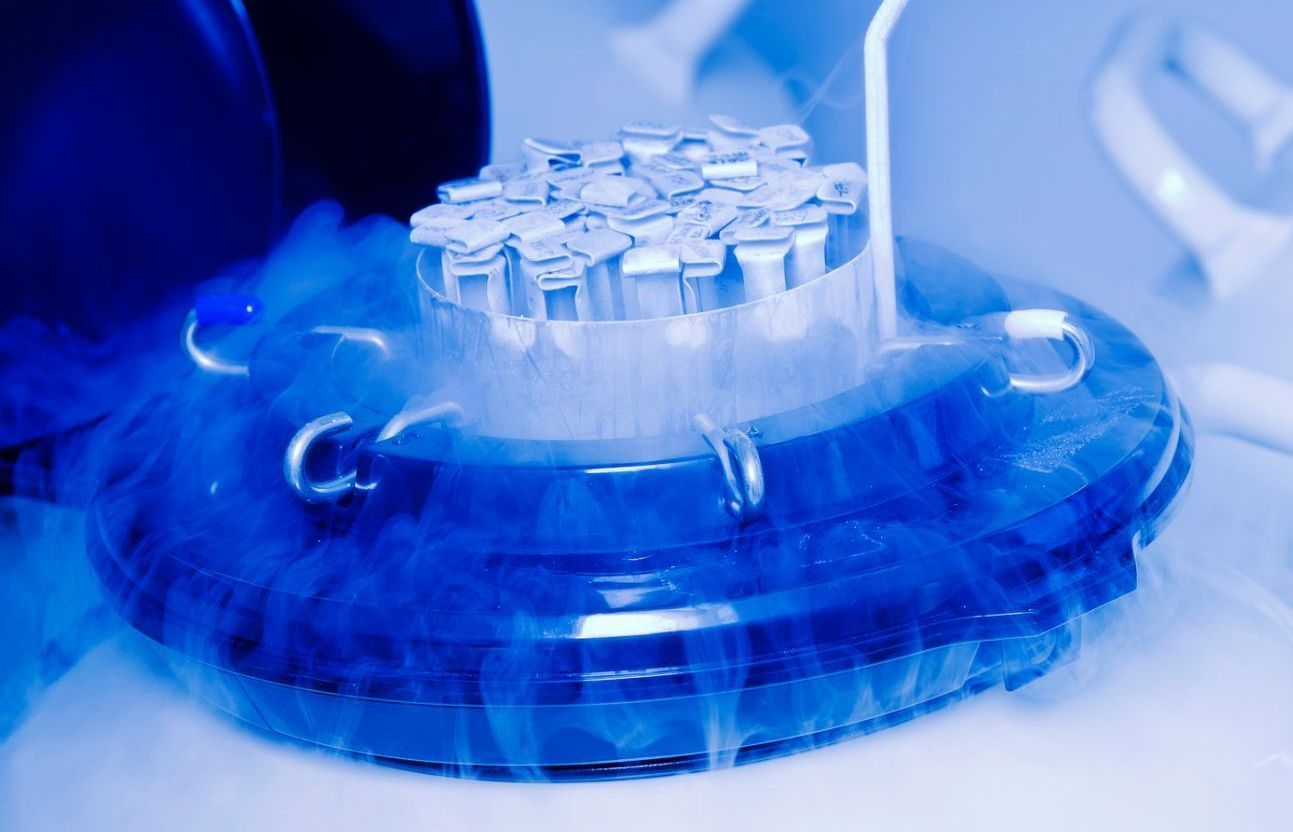

Cold Chain Logistics; the system of warehousing, transportation and delivery of temperature-sensitive products at the consistent temperature required throughout. Consistent stable temperature is especially important for businesses that supply perishable products where quality can be impacted by fluctuations in temperature. Effective cold chain logistics and management helps to reduce product damage and waste, as well as ensure that clients receive products that have been kept within the correct conditions.

The benefits of cold chain logistics and management for businesses include increased control over their inventory, improved efficiency, reduced costs associated with spoilage or incorrect handling, and greater customer satisfaction. By investing in this type of solution, businesses can have complete visibility over their temperature-sensitive products which will enable them to optimise operations in order to improve overall efficiency across the board. Additionally, cold chain logistics solutions can provide real-time tracking so business owners can monitor the conditions of their products throughout every step of the journey. This gives business owners an understanding of any potential issues before they arise; allowing them to take corrective action quickly and efficiently.

When implementing an effective cold chain logistics system, it’s essential to invest in reliable asset tracking devices. Asset tracking devices allow you to track your products’ temperature during transport and storage amongst other conditions. These devices are crucial for keeping your products safe during transit by collecting data on temperature and notifying concerned parties when violations of conditions are experienced. Additionally, these devices are also beneficial for ensuring regulatory compliance with government standards and any regulations set by businesses producing the goods.

To ensure that your cold chain logistics system runs smoothly from start to finish, it’s important to create robust policies regarding how goods should be handled at every stage of their journey from production through to delivery. Businesses should also focus on optimising their cold chain processes by using automation tools wherever possible. It’s also important to invest in training personnel involved in daily operations so they understand how best to handle temperature-sensitive products properly from start to finish including any solutions deployed. Finally, comprehensive monitoring and analytics should be used throughout the process so businesses can identify any potential challenges experienced early on before they become serious issues further down the line.

In conclusion, investing in a robust cold chain logistics solution provides numerous benefits for businesses looking to improve their inventory management systems while ensuring that all customers receive goods that have been held within the correct conditions during transit or storage. Reliable asset tracking devices along with comprehensive policies regarding handling procedures combined with continuous monitoring and analytics; businesses can be rest assured that their goods will remain within the correct conditions while providing maximum efficiency across the entire cold chain - ultimately leading to improved customer satisfaction alongside minimal wastage or product damage due to mishandling or products being exposed to fluctuations of set conditions.

What Is Cold Chain Logistics?

Cold chain logistics is a term that refers to the temperature-controlled storage and transportation of perishable goods. It is especially important for businesses dealing with food and pharmaceutical products, as these are highly sensitive to fluctuations in temperature which in turn can negatively impact product quality. The cold chain system includes processes such as refrigerated trucks and containers, temperature monitoring systems, and timely delivery of products to ensure they remain in optimal condition throughout the entire journey.

In order to maintain a successful cold chain logistics process, businesses must not only have the right equipment in place but also have efficient cold chain management processes in place. This includes regular inspections, preventive maintenance checks, and accurate tracking of all shipments. The use of reliable hardware and software solutions combined can help keep track of temperature experienced during transit, notify staff when items have experienced violations of conditions, and also provide real-time visibility.

Aside from asset tracking solutions monitoring the conditions that products are exposed to ultimately ensuring product quality has been maintained, companies can also realise other benefits from using cold chain logistics solutions. For example, it helps reduce wastage and damage of products, allows proactive action to take place once personnel are notified and for decisions taken to be backed by data.

Overall, cold chain logistics solutions offer a wide range of advantages for businesses dealing with highly sensitive goods like food and pharmaceuticals. From improved product quality assurance and cost savings, optimised cold chains to more efficient operations overall – there are many reasons why every business should consider incorporating this technology into their operations today.

Benefits Of Cold Chain Logistics Solutions

Such As Asset Tracking Devices For Businesses

Businesses in the food, pharmaceutical, and chemical industries face unique logistical challenges to ensure product quality is maintained. Cold chain logistics solutions such as asset tracking devices are an increasingly popular solution that offers a number of benefits. Cold chain management involves the management of processes throughout the entire cold chain from manufacturing, storage and distribution. Effective cold chain management is crucial for businesses that transport temperature-sensitive goods as it helps to ensure products remain safe, viable and of high quality when they reach customers.

One of the primary benefits of cold chain logistics solutions for businesses is the ability to ensure product safety and the overall quality has been maintained due to the conditions the products have been kept in. Storing goods within correct temperature ranges will prevent them from spoiling or growing bacteria before they reach their final destination. This helps reduce waste and increases customer satisfaction by ensuring that products arrive in perfect condition.

In addition to maintaining product safety, cold chain logistics solutions also provide cost savings for businesses. Keeping perishables at specific temperatures requires more energy than other storage methods; however, taking advantage of asset tracking solutions can help businesses save money in the long run by reducing spoilage rates thereby ensuring minimal products have to be re-shipped and preventing wasted resources.

Finally, implementing effective cold chain management processes has allowed many businesses to increase their competitive advantages over other companies in their industry due to improved customer service and satisfaction levels, as well as increased efficiency in managing the cold chain process with fewer delays or errors. Customers have come to expect consistently high-quality goods delivered on time and with minimal waste; utilising a reliable cold chain system can help businesses achieve this goal while still keeping costs low.

Overall, there are numerous advantages for businesses who use cold chain logistics solutions for their operations. Not only does it maintain product quality and safety but it can also provide cost savings along with improved customer service levels which can give companies an edge over competitors in their industry.

Different Asset Tracking Devices For A Successful Cold Chain Solution

When it comes to maintaining the safety and integrity of cold chain shipments, asset tracking devices are a crucial component. These devices enable businesses to track the whereabouts and condition of their shipments as they’re transported. By using specialised tracking devices, businesses can ensure that their goods are not exposed to significant temperature fluctuations or other environmental hazards that could potentially cause spoilage or damage. In addition, asset tracking devices allow businesses to monitor and respond quickly in cases of lost assets, theft or mishandling of products.

Modern asset tracking devices come in a variety of forms and can be tailored to specific needs and requirements. For example, active tracking solutions are designed to provide real-time location information for a shipment as it moves from point A to point B. In addition, they commonly have other built-in sensors that can detect temperature changes or other environmental conditions that could lead to spoilage or damage.

The KELVIN solution range from Adapt Ideations is an advanced product designed to monitor and record a wide range of environmental parameters. The data loggers are an active tracking solution that enables data to be sent to the secured-cloud portal allowing for convenient data management and the ability for all stakeholders to easily view the data at any point of time. Additionally, it can monitor vital conditions including temperature, location, shock and light exposure. When the violations of conditions occur, they immediately result in a notification being sent out. With all these advanced features, the KELVIN data logger range is a powerful tool for monitoring moving assets across different industries such as food & beverages, life sciences, cold chain logistics and more.

Other types of tracking solutions include passive data loggers, RFID tags, GPS & Bluetooth trackers which offer alternative ways to track products. No matter which type of tracker you choose, all asset tracking solutions offer similar benefits depending on the solution in use: improved visibility into goods during transit; improved security against theft or mishandling; monitoring of temperature; and greater accuracy when it comes to item identification and shipping details. With all these advantages combined, it’s clear why an effective asset tracking solution is essential for successful cold chain monitoring.

How To Implement A Robust Cold Chain Logistics System

When implementing a robust cold chain logistics system, there are several steps to take in order to ensure that the system runs smoothly. First, it is essential to have an inventory management system in place. This must include accurate tracking of the location and condition of all items in the cold chain. This information should be easily accessible at any time so that employees can quickly locate and manage inventory. Additionally, it is important to have a reliable shipping method in order to keep goods from being contaminated or damaged as they travel through the cold chain. Lastly, there must be an asset tracking and monitoring solution in place to effectively monitor conditions of products throughout the cold chain logistics system. All of these factors combined will help create a strong cold chain logistics system that operates efficiently and effectively at all times.

The Benefits Of Investing In Cold Chain Logistics Solutions

Investing in cold chain logistics solutions can be highly beneficial for businesses of all sizes, allowing them to reduce costs, increase efficiency, and ensure product quality has been maintained due to conditions monitored. Cold chain logistics refers to the transport of temperature-sensitive products. These systems are designed to ensure that products remain within certain temperature parameters throughout the entire journey, from origin to destination. This is especially important when dealing with perishable items like food, pharmaceuticals, and medical supplies.

Investing in this technology also improves customer satisfaction as a result of less wastage and fewer returns due to damaged goods. Furthermore, businesses can also benefit from improved brand reputation as customers are more likely to purchase items from companies that provide reliable delivery services. Additionally, investing in asset tracking solutions designed for temperature-sensitive goods helps companies ensure regulatory compliance has been maintained.

Overall, investing in cold chain logistics solutions offers numerous benefits for businesses of all sizes. Not only does this technology help reduce costs and increase efficiency but it also provides various ways for companies to improve customer satisfaction and ensure product quality has been maintained throughout the cold chain.

To learn more about the advantages of investing in cold chain logistics solutions and how they can help improve the efficiency and profitability of your business, contact Adapt Ideations today.

Common FAQ's

A cold chain is a temperature-controlled supply chain consisting of the transportation and storage of perishable items. It is designed to maintain the quality and freshness of food, pharmaceuticals, chemicals, and other temperature-sensitive products by keeping them at their optimal temperature range throughout the entire journey. This ensures that products are not spoiled before reaching their final destination. The cold chain requires refrigerated trucks, warehouses, and packaging techniques to protect products from set temperatures.

A wide variety of goods can be transported through a cold chain, including foods such as fruits and vegetables, dairy products, meat, fish, poultry and other proteins; pharmaceuticals; medical supplies; vaccines; chemicals; and even non-perishable items such as flowers or electrical components. All these items must remain within specified temperature ranges in order to maintain their integrity during transport.

Transport and storage of all goods shipped through a cold chain must adhere to strict temperature standards established by national or international authorities. For example, if transporting perishable food items like dairy or fish, recommended temperatures typically range between 2 - 8°C (36°F – 46°F). Additionally, it’s important to take into account any fluctuations in external temperature along the route which could potentially affect the internal cargo temperatures.

A successful cold chain logistics operation needs several components to ensure safe transport and on-time delivery: Qualified warehouse staff with good knowledge of temperature-sensitive product safety practices; dedicated trucks with appropriate refrigeration systems; asset tracking solutions to monitor shipments in real-time; proper packaging materials that provide an effective barrier between cargo and outside environment; specialised software solutions for monitoring and reporting; and standardised protocols for quality control at each stage of transit.

The main difference between a cold chain and supply chain lies in its purpose: while the latter is focused on delivering goods from point A to point B efficiently at low costs, the former is designed specifically for transporting temperature-sensitive products safely over longer distances without compromising product quality. The need for insulation materials that guarantee proper temperatures throughout transit increases costs compared to traditional supply chains but it enables businesses to deliver fresh items with full confidence that they will arrive in satisfactory condition at their final destination.

Cold chain technology offers many advantages to businesses and individuals, including temperature-controlled storage and transportation of temperature-sensitive products, such as pharmaceuticals and food items. Cold chain systems help to ensure that these products remain in optimum condition throughout their journey from production to consumption.

This increases the safety and quality of food items, and helps to protect the integrity of medications. In addition, cold chain systems can significantly reduce product wastage due to spoilage, providing cost savings for companies who use them. Furthermore, cold chains are becoming increasingly important for compliance purposes in various industries such as food production and pharma manufacturing as they help maintain traceability and transparency during transport. Finally, they can also be used to track inventory while in transit in order to better manage logistics operations.

Cold chain logistics comes with certain risks which must be managed appropriately in order to ensure that products remain safe throughout their journey from origin to destination. Temperature fluctuations or deviations outside pre-set parameters can cause a wide range of quality issues depending on the particular product being shipped, from spoilage and contamination issues in food products to reduced efficacy and even health hazards for medications which have been compromised by exposure to temperatures outside of their specified range. In addition, there is also a risk that a product might not reach its destination at all if products have been compromised and is no longer viable.

A number of trends have emerged over recent years which have pushed cold chain risk management strategies forward, and these include increasing consumer demand for transparency around where their food has come from; increased regulatory scrutiny around how pharmaceuticals are transported; as well as technological advancements enabling more efficient tracking and monitoring of goods while they’re in transit. Additionally, government initiatives around reducing emissions through ‘green’ transportation methods have provided an incentive for businesses looking into optimising their supply chains through the use of new technologies.

IoT enabled cold chain monitoring offers a number of benefits, such as the ability to:

• Automate and streamline the temperature monitoring process; enabling businesses to track their products in real-time.

• Reduce the amount of manual labor needed for cold chain monitoring due to sensors that can detect data in an automated manner.

• Have greater visibility into product quality and shelf life with automatic alerts when items exceed their specified temperatures or humidity thresholds.

• Increase client satisfaction by providing clients with more precise information about their orders and ensuring delivery on time, every time.

• Improve inventory management by accurately tracking items throughout the cold chain, allowing businesses to avoid losses due to spoilage or delays in shipment.

• Reduce costs associated with spoilage due to inaccurate cold chain monitoring and eliminate unnecessary expenses related to inefficient processes.

Overall, IoT enabled cold chain monitoring solutions provide a range of benefits that can help businesses save time and money while maintaining quality assurance for both their products and customers.

Active cold chain monitoring can be implemented using a variety of methods, depending on the size and complexity of your business’ system:

• Utilise asset tracking and monitoring solutions throughout all points along your supply chain that are capable of continuously tracking temperatures, humidity levels, location data, etc., in order to monitor products in real-time during transport or while they are stored onsite.

• Receive instant notifications that allow you to easily access cold chain data and be notified of any violations of conditions

• Make use of cloud platform solutions that gather data utilised for comprehensive reporting which enable you to identify trends over time and plan for future needs accordingly.

Overall, implementing active cold chain monitoring is essential for businesses looking to stay ahead of the competition by ensuring timely deliveries and product safety across all operations and product journeys.

Get in touch with us today at enquiries@adaptideations.com for further information on our solutions.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.

Our Guides.

Sign up to our monthly newsletter!

Thank you for signing up.

Please try again later