The Changing Industry Standards Of Traceability & Compliance For Perishable Goods

The correlation between asset tracking and perishable goods:

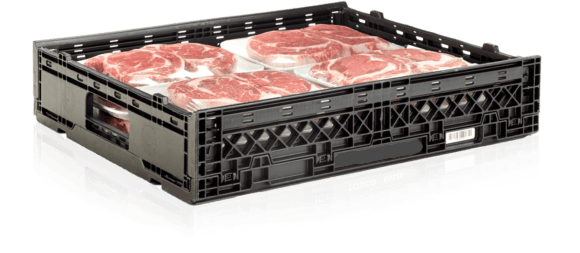

Asset tracking is the process of monitoring the status of a shipment in transit. Companies across the globe have been making use of this innovative method to ensure that their shipments arrive at the designated location in good condition. There are a variety of goods that can benefit from a track and trace solution, ranging from valuable artwork to vaccines and even perishable goods such as food and beverages. Perishable goods are products that have a best before or expiration date, such as fresh produce, meats or beverages, and therefore need to be kept in very specific conditions during the transportation process.

In order to avoid a cold chain breach, it is imperative that the correct track and trace solution is utilised to transport such sensitive goods. A few examples of popular types of asset trackers include barcode scanning, Bluetooth, GPS, and RFID. The most popular type used as a cold chain logistics solution due to its sustainability and accuracy is known as a

data logger. Data logging devices are an active asset tracking technology that offers insight into the temperature, location, light and shock occurring within an active shipment. They are lightweight, portable, and extremely user-friendly as data is able to be downloaded and analysed in order to improve on the company’s cold chain management processes.

What are food traceability standards?

Food traceability standards are an extremely important requirement necessary to allow perishable goods to be able to move through the supply chain. Whilst general traceability refers to broader visibility of a shipment, with food traceability there are more intricate factors that have to be considered. These factors include but are not limited to ingredients, raw materials, additives, and packaging. When it comes to food traceability and compliance for Australia and New Zealand, the first place to go when seeking further information is Food Standards Australia New Zealand (FSANZ).

FSANZ is a regulatory government agency that comes under the Australian Government Health Portfolio and was created under the Food Standards Australia New Zealand Act 1991 (FSANZ Act). It enforces standards to maintain compliance and moderate the use of processed ingredients, such as additives and colours, in consumable goods, i.e., food and beverages.

To keep track of every perishable product available, there is an intricate system that holds all relevant product records ranging from name and address of supplier to volume of product being transported. In addition to administrative records, the physical goods also need to be monitored in order to avoid a situation where food recall is necessary, such as damage or spoilage of product due to a cold chain breach. This is where active data logging devices play a significant role in assisting the cold chain management process.

How do data loggers make a change?

Data loggers are a great cold chain logistics solution as they offer enhanced visibility on a host of vital metrics, including temperature, location, light and shock. This sustainable system allows the client to hand over all monitoring responsibilities not only for the duration of the shipments journey, but also when the goods are kept in storage facilities. There are a variety of data loggers available, each focused on solving specific pain points in the industry.

When it comes to cold chain management in particular, temperature and light are usually the most significant violations that must be monitored, as perishable goods such as food and beverage can easily be compromised either through damage or spoilage. To combat this possibility, data loggers have the ability to monitor a shipment throughout transit and return data periodically, alerting the client of the status of the goods. This ensures that as soon as a violation occurs, action can be taken to rectify the problem therefore avoiding wastage of product, financial loss and inability to deliver to the customer.

Active data loggers are not only able to track live shipments, but they also excel at monitoring goods that are in cold storage facilities. By constantly notifying the client of the temperature of goods, the loggers help to ensure that the climate within the storage warehouse is constant and does not fluctuate, avoiding spoilage of the stationary products within.

Where can Adapt Ideations get involved?

As discussed, data loggers are extremely helpful cold chain logistics solutions, whether they are tracking the status of live shipments or monitoring the temperature conditions within a cold storage facility. At Adapt Ideations, we offer a wide host of versatile and effective

data logging solutions. Our primary range consists of three main product families, namely

KELVIN,

PIXEL, and

PROTON. The KELVIN range consists of our all-rounder solution, providing near-real time data alerts on temperature, location, light and shock violations. Our PIXEL products are also intrinsically involved in the perishable goods sector, as they monitor temperature and humidity conditions within cold chain storage facilities. Paired with our in-house secured cloud platform, clients can download data that can be further analysed to avoid future risk of damage or loss of product and therefore enhance their cold chain management processes. Similarly, the PROTON range can track temperature, however these USB loggers are single-use making them a simple and affordable solution for cold chain logistics.

Get in touch with us today at enquiries@adaptideations.com for further information on our solutions.

Share Our Post.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.