5 Ways to Increase Efficiency With Innovative Cold Chain Management

What Is Cold Chain Management?

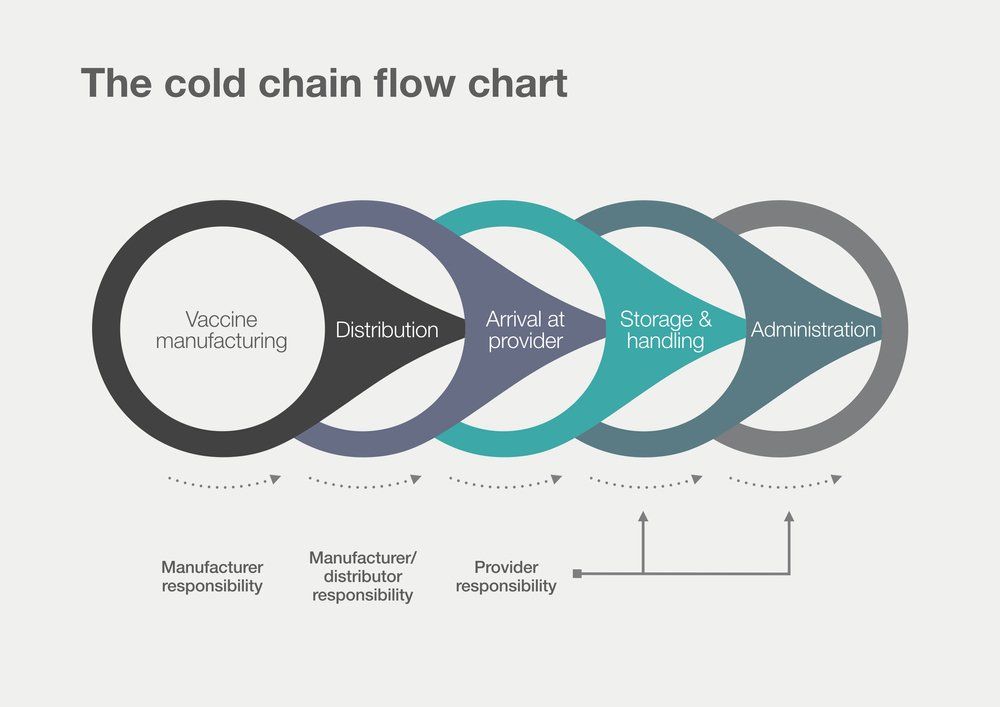

Cold chain management is the process in which temperature-sensitive goods is monitored and maintained throughout the entire cold chain from beginning to end. In order for cold chain management to be effective meticulous coordination between all parties and touch points are required including how products are monitored. The cold chain encompasses a wide range of products including vaccines, meat, and other perishable goods.

Without well-planned and executed cold chain management, there is a significant risk of these valuable and potentially high-value perishable goods going to waste in the supply chain. For example, according to the NSW Department of Health, vaccines are no longer safe for use when they exceed the temperature range of 2°C to 8°C, although vaccines may be required to be kept in other temperature ranges.

If violations of these conditions occur there is a significant risk that they will lose their effectiveness or may become unsafe for use. Damage and waste to such products can cause flow on effects such as having to reorder products that have gone to waste, a lack of remaining product in stock, and high levels of product damage.

There are always hurdles in any process, including general supply chain management. However, when it comes to cold chain management specifically, challenges that seem small at first can often have larger repercussions. This is why it is important to identify these faults and find solutions to overcome them.

1. Understand What Products Need To Be Monitored.

An important aspect to the cold chain management process is understanding what products need to be monitored, the conditions that they should be maintained at and the processes that will be required to remedy violations if they occur. This is how you will be able to then identify what kind of solution is needed in order to satisfy requirements.

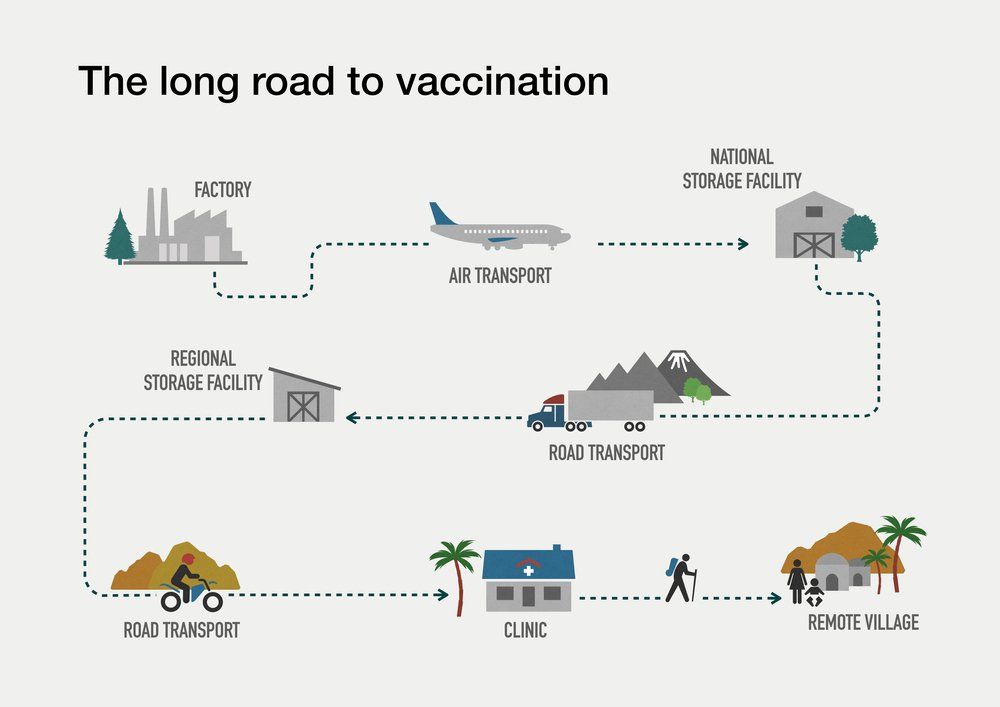

One aspect of the cold chain sector is the transport of vaccines, which must remain within a temperature range most commonly 2°C to 8°C. Temperature is only one aspect as vaccines are also sensitive to other environmental conditions, they can be highly fragile and often have some degree of time-sensitivity.

Due to the nature of perishable goods, they can be easily susceptible to damage. After this analysis, the conclusive statement is that vaccines require temperature monitoring along with additional near real-time data on location tracking and tamper detection in order to be safely transported through the temperature controlled supply chain.

2. Greater Visibility With Cold Chain Data Loggers.

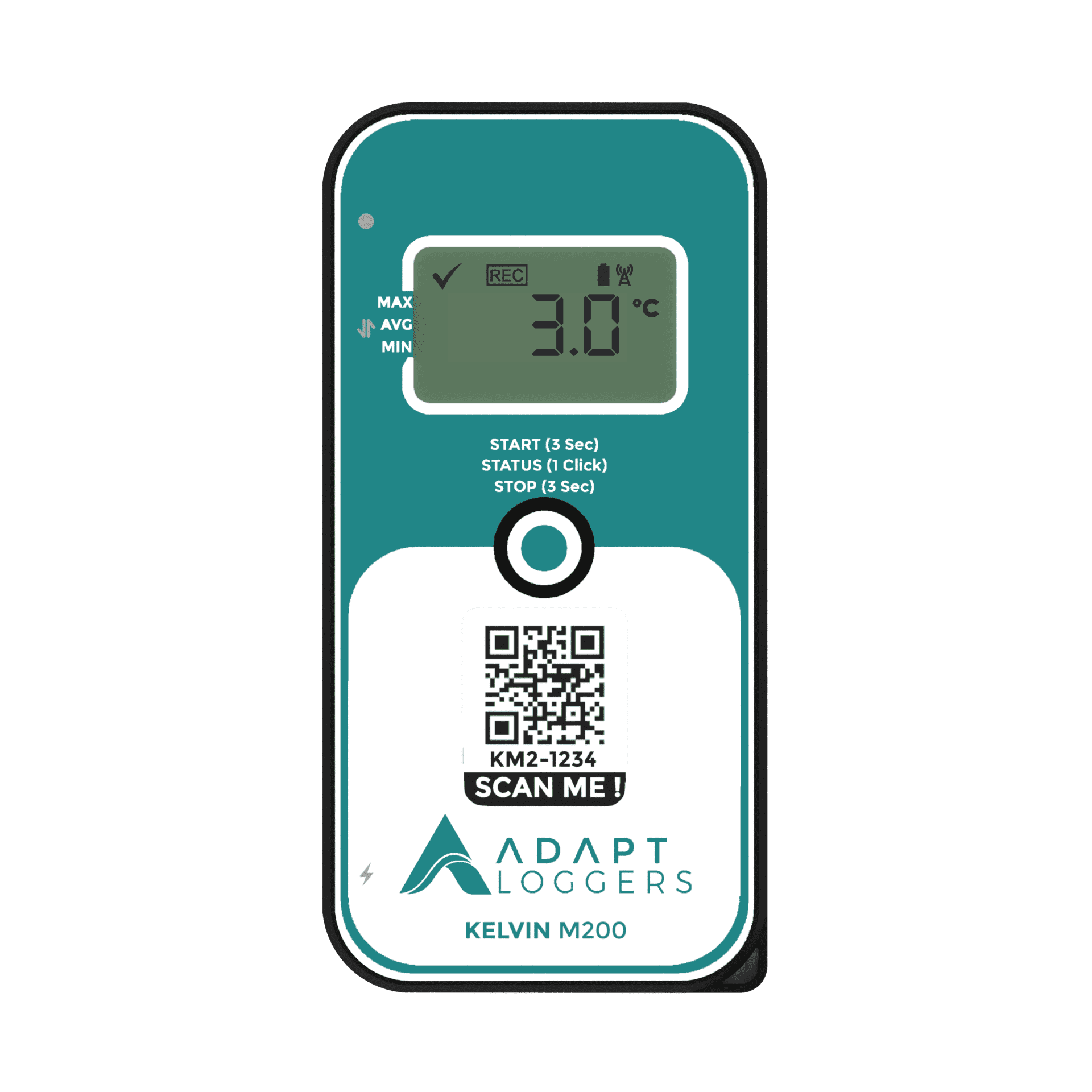

Consistent visibility is a key factor in maintaining well-managed cold chain procedures in the cold chain industry. The easiest way to gain clarity on the status of a temperature-sensitive shipment is by utilising a near real-time asset tracking device. Cold chain data loggers are primarily used for these kinds of consignments as they are able to track the temperature of goods such as vaccines and meat in intervals and accurately record and transmit data via the cloud.

The information collected on temperature sensitive products can reveal any challenges experienced throughout the cold chain process being monitored, which can then be used to learn and adapt these procedures to achieve a better outcome in the future. Near real-time cold chain data loggers allow stakeholders to take proactive action when violations of conditions occur. This enables violations of set conditions of perishable goods to potentially be rectified saving products from being damaged and going to waste.

3. Remain Agile By Preparing For The Unexpected.

When dealing with perishable goods, the possibility of a cold chain breach occurring is always present. Therefore, anticipating every possible risk, understanding them and being armed with simple yet effective solutions will ensure greater cold chain management. For example, there may be a scenario where a shipment of vaccines that is being tracked indicates the temperature has fluctuated and therefore exceeded the recommended temperature. The use of a near real-time cold chain data logger allows instant alerts to be sent when violations occur.

This effectively enables the opportunity for corrective action to take place to ensure the consignment remains compliant on temperature sensitive products. If this same shipment had utilised a passive cold chain data logger instead stakeholders may not have been able to understand violations had occurred before the shipment reached its final destination. Therefore, always remaining prepared for these breaches to occur is imperative in maintaining effective cold chain management processes.

4. Constant Communication Is Key.

If there is ever a hurdle within the cold chain management process that can easily be avoided, it may likely occur due to a lack of communication. By not having the ability to readily and easily share information with stakeholders throughout the cold chain can lead to a lack of visibility. However, communication can be simplified through the use of near real-time cold chain data loggers.

With Adapt Ideations’

KELVIN Suite Of Devices via our dashboard, reports can be easily shared with others and levels of access can be applied to enable stakeholders to view data on consignments in near real-time. The auditing aspect allows for an audit trail on the dashboard to be viewed for example allowing a greater understanding of who has added consignments.

5. Identify A Solution That Will Be The Best Fit.

Some of the ongoing problems in cold chain management have already been identified above including lack of consistent visibility and experiencing unexpected challenges. The biggest question remains, how can these issues be resolved? One solution that can offer an easy answer to this burning question and as a result further enhance cold chain management, is finding the right asset tracking and monitoring solution that best suits the needs of your temperature sensitive products.

With many providers offering data loggers, companies need to develop a comprehensive understanding of the provider’s offerings and advantages and disadvantages of their data loggers and whether they can meet their needs.

Such questions that may be asked are;

- Do their solutions meet our quality requirements?

- How accurate is the data collected and how is it communicated?

- What is the cost and how can the solution be deployed at scale?

- What is the timeframe in which they can deploy the solution?, and

- What security protocols are in place?

Only once these questions have been answered can a company identify if a provider will be the best fit.

How Can Adapt Ideations Help Streamline Cold Chain Management?

Here at Adapt Ideations, we offer a range of innovative asset tracking and monitoring solutions that can help improve cold chain management for temperature sensitive products. Working closely with a number of clients involved in the cold chain sector has led us to where we are today. We’re proud to announce the launch of our next-generation data loggers on the 15th August. Our third-generation data loggers have a range of enhanced features and longer battery life.

For more information get in touch with us today at enquiries@adaptideations.com or place an order directly via our ecommerce website Adapt Loggers.

Enquire to find out more about our innovative solutions and how they can be utilised at enquiries@adaptideations.com

Share Our Post.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.