Data Loggers - Everything You Need To Know

What Is A Data Logger?

A data logger is a device that monitors and records conditions that assets are exposed to over a set period of time. The service which these devices perform is generally referred to as asset monitoring. They enable the remote tracking of physical assets using both hardware and software. A range of solutions exist today including single-use, reusable, passive and near real-time solutions. While data loggers can be utilised across a wide range of industries, they are commonly utilised across cold chain logistics, biopharmaceuticals and food & beverages sectors.

The electronic devices are fitted with sensors or an external attachment such as a probe which monitors, detects, and records data. Near real-time solutions also have the capability to allow data and alerts to be received as soon as they occur. With significant advancements in technology near real-time solutions are helping users to go from passive solutions to digital data loggers. Real-time data loggers are automating and simplifying the tracking of valuable assets.

Data loggers have the ability to monitor a range of metrics depending on the sensors utilised. In many instances asset tracking companies provide a range of solutions which can cater to different use cases. These devices can monitor vital data for example on temperature, humidity, location, light, and shock in order for companies to gain deeper insights into their operations.

Data loggers can also help identify challenges and trends that may be experienced enabling supply chain stakeholders to take action when required. This can have a range of short and long-term benefits such as ensuring assets are being handled and stored correctly, improve compliance processes, and reduce asset damage & waste. In the long term this will enable companies to update current processes in place and enhance their operations allowing a more functional and resilient supply chain to be developed.

Common Uses For Data Loggers?

Data loggers can be utilised across a variety of industries although most commonly they are used to monitor temperature-sensitive and high-value assets. Data loggers are frequently used for monitoring perishable foods and pharmaceutical consignments. Using these solutions ensures that the goods will remain in ideal conditions during transit and violations of conditions can quickly be identified.

Data loggers can be utilised across all industries including the monitoring of reusable assets, fine arts, storage facilities, data storage and vehicle fleets. Common features of data loggers include location tracking and temperature monitoring allowing them to be applied widely to almost every industry.

One of the best uses for data loggers is to achieve greater visibility on assets throughout the supply chain. As supply chains are often complex and products pass multiple hands, an important component that needs to exist is visibility. Data loggers are a reliable and time-efficient monitoring solution for any company that requires asset monitoring to be in place.

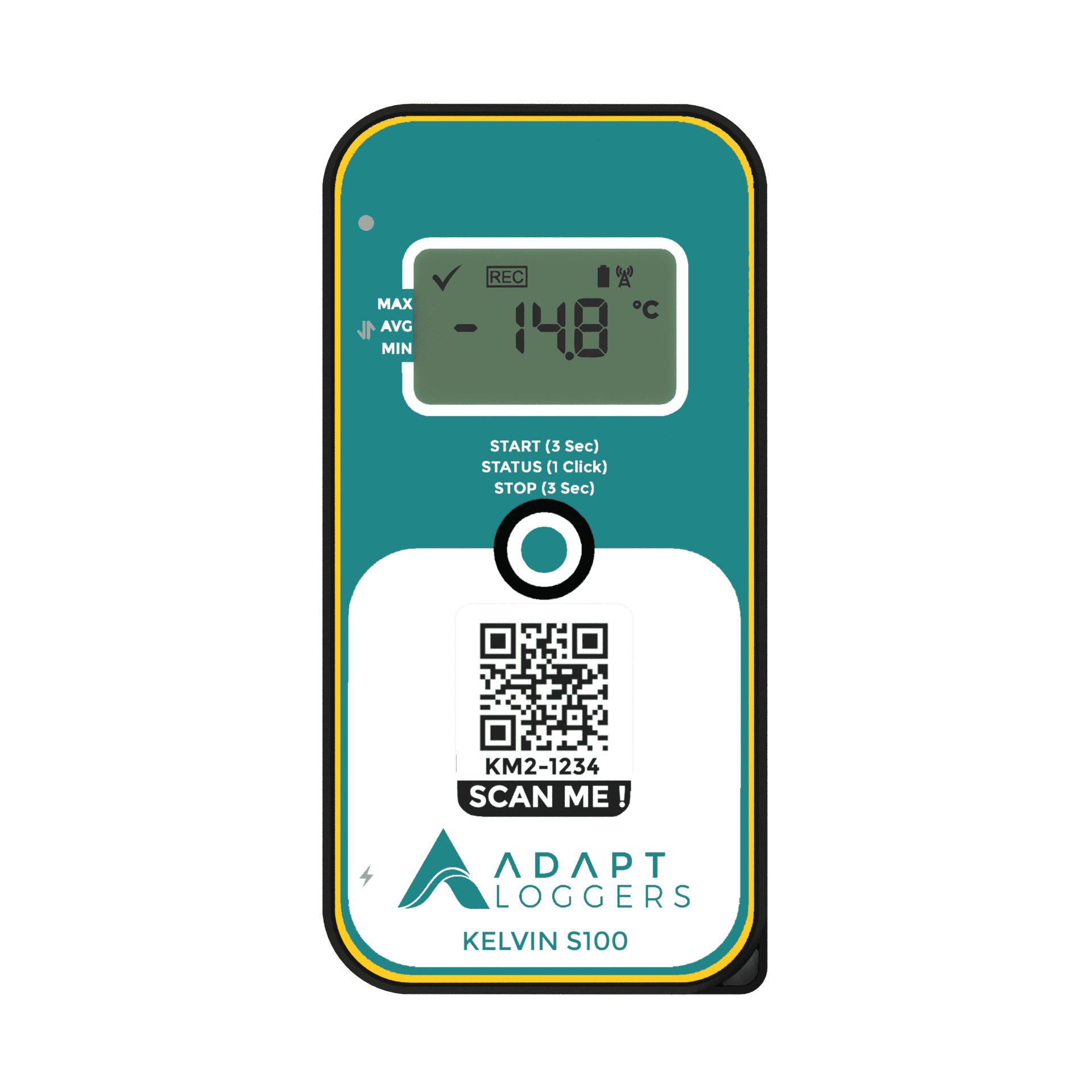

Some of the key advantages of data loggers and the data collected is the high accuracy, ease of use, greater supply chain visibility, simplified compliance processes, and the digitalisation of monitoring it provides. In addition to those advantages, the next generation of loggers offered by Adapt Ideations helps simplify compliance further by allowing stakeholders to understand if a violation has occurred instantly with the LCD display on devices.

What Type Of Assets Benefit From A Data Logger?

Assets that best benefit from the use of data loggers are any goods that are high-value, temperature-sensitive or fragile. Supply chains are often complex with multiple touch points for each and every product highlighting the need for stringent monitoring to ensure that high-level supply chain visibility between key supply chain stakeholders is maintained. Another reason why data loggers are advantageous is that they ensure compliance and regulation measures are adhered to in highly regulated sectors. This includes biopharmaceuticals such as vaccines and serums which are globally distributed.

The transport of these highly vital and in-demand products must follow appropriate regulations such as traceability and visibility of conditions experienced. An example of a product journey could consist of a temperature-sensitive product such as meat being transported over a number of weeks in shipping containers.

Key Decisions

Driven By Data Analysis.

A lack of visibility can often be experienced and products can potentially experience multiple violations of conditions throughout its journey. In this case, a data logger can be used to collect vital data on conditions of the assets. While the data may not be received in real-time while the shipment is out at sea, once the products are received supply chain stakeholders can instantly understand if products remain viable for consumption. Insights can also be developed from the data collected allowing decisions to be backed by data improving everyday operations.

Data loggers can provide greater transparency and ensure a chain of custody is present. Supply chain visibility enhances the ability and accuracy to track different goods in transit, giving a clear insight into vital conditions of assets.

Data loggers can also assist logistics partners to understand conditions experienced by assets thereby reducing disruptions and risks associated with lack of visibility. Further to this, alerts from real-time data loggers encourages action to be taken before major violations of set conditions occur in turn reducing costs associated with damage and waste of products. The use of temperature data loggers by industries that handle perishable goods and/or assets with a high degree of sensitivity to changes in the environment could yield considerable benefits.

Where Can a Data Logger Be Used?

Data loggers are extremely versatile and can be utilised as monitoring devices in every industry today to monitor conditions of assets. Data loggers can have a number of sensors and embedded technology within them that allows conditions such as temperature, location, and even light and shock to be detected and monitored with data storage. How these solutions can be utilised and what type of data logger should be used comes back to what the use case or challenge experienced is.

While they track certain parameters and conditions, it’s also important for these devices to meet certain industry standards such as IP grade ratings. Certain tests can be undertaken to ensure that these solutions are protected from certain elements such as dust and water. Without meeting these ratings, devices can easily become damaged and data collection can be impacted.

Data loggers can be used in a range of ways such as tracking products throughout the entire supply chain going between different points, tracking reusable supply chain assets, and monitoring assets in cold storage. Most commonly temperature-sensitive or high-value assets such as vaccines, meat, or even valuable artwork are tracked during transportation to ensure they remain within the set conditions required.

For supply chains, Data Loggers can be used in OTFI (On Time In Full) metrics used to measure the success of a company's delivery process by calculating the percentage of on-time deliveries vs. late deliveries. Data loggers can assist this by providing vital data and track the status and locations of their shipments.

By utilising innovative data loggers companies can easily collect data and share data with their clients or other supply chain stakeholders allowing greater transparency between all parties involved.

Data Logging Solutions That Work.

One of our leading solutions are our KELVIN data loggers offering features such as real time location tracking, temperature data, and light & shock detection. The ping interval and notification method can all be customised based on a client’s preference.

Adapt Ideations offers a dashboard view for clients in which you can see the exact path that your assets are travelling on, including the ping locations and an events log where any violations along the journey are noted. The solution also features geofencing, which can be added when creating a trip for a device. Geofencing allows the user to add a boundary around certain location points along the planned trip and receive specific alerts when the device enters or leaves that area.

The straightforward yet effective and easy to use data loggers helps to simplify everyday asset management functions and increase visibility for our clients. Often times, some assets that are being transported are sensitive to certain environmental conditions such as temperature data, humidity or shock. A clear example of this can be found within the cold chain sector, specifically with vaccines or serums. In this case, a client would not only track the location and temperature of the asset, but additionally any shock and light exposure.

While the use of a passive solution or USB data logger are used widely throughout by the pharma industry today, near real-time and reusable solutions are paving the way forward allowing companies to take proactive actions when violations of set conditions occur. This enables companies to take necessary action ensuring damage and waste of assets are avoided.

Adapt Ideations’ wireless data logger solutions offer a deeper insight into the violations occurring in transit, sending notifications when assets experience temperature violations and shock, or even if the packages are opened before reaching their destination. This extra layer of protection creates a clear window between the user and supply chain processes.

IoT enabled asset tracking and monitoring solutions.

What Are The Different Types Of Data Loggers?

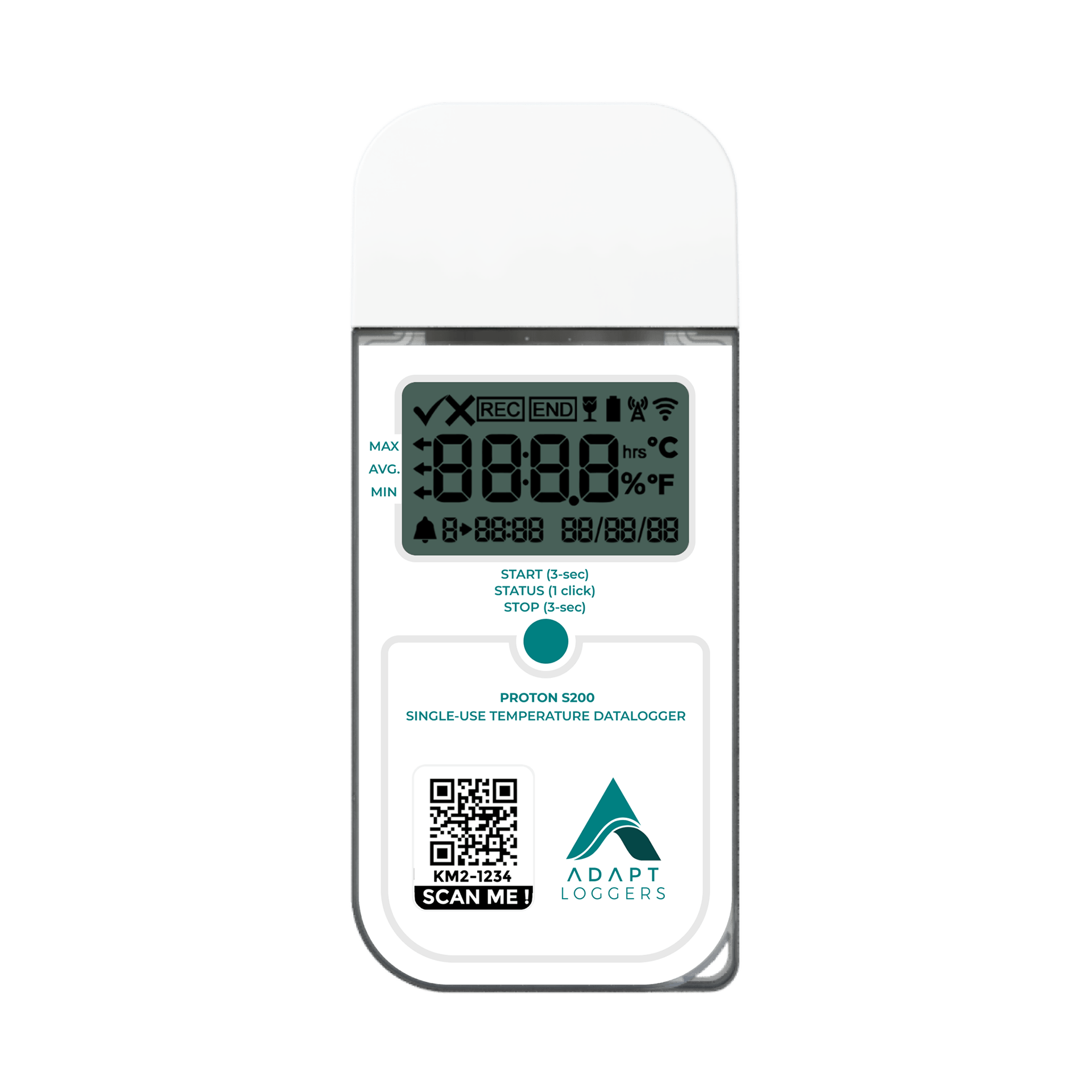

There are multiple variations of data loggers present in the market, all created to resolve specific challenges or to be used for particular use cases. Single-use data loggers, data loggers with probes and warehouse monitoring loggers are some of the most common types of data loggers available and are utilised globally.

Many other types of data loggers also exist such as wireless cellular data loggers and USB data loggers. Each solution has a different purpose and can each benefit a range of market sectors.

1. Single-Use Data Logger.

Single-Use data loggers are utilised commonly to monitor consignments and then are discarded after the one use. Often, they are utilised to eliminate the need for reverse logistics and are very cost-effective. Common features include temperature and location monitoring capabilities to accurately collect vital data on assets.

The data collected can then be downloaded to be analysed, and business decisions can be made upon the findings. Innovative single-use data logger devices can also feature an LCD display allowing compliance to be made easier for any supply chain stakeholder to understand. This allows anyone to quickly identify if a violation has occurred during the product’s journey.

2. Data Logger With Probe.

Data loggers with probes are another variation of asset tracking solutions commonly used for products that require ultra-negative temperature monitoring. These solutions were widely utilised for the global distribution of the Covid-19 vaccines due to the need to preserve the goods in extremely low temperatures.

Other products that can require monitoring via a data logger with a probe are serums and various biopharmaceuticals requiring ultra-negative temperature monitoring. Ensuring that temperature-sensitive goods such as biopharmaceuticals are monitored will enable pharmaceutical companies and associated partners & clients to reduce costs associated with damage and waste of products that experience violations of set conditions.

3. Cold Storage Monitoring Logger.

Monitoring assets during storage is also vital for greater visibility of temperature-sensitive products. Assets such as some perishable foods and pharmaceuticals are stored before, during and after being transported to their final destination.

Cold storage monitoring loggers enable greater automation of monitoring processes in place and allow alerts to be sent when violations of conditions occur. Utilising cold storage monitoring loggers can also enable greater visibility of assets with data being able to be shared with clients easily. The entire supply chain from the point of origin to the destination must be closely monitored in order to provide greater security and transparency to clients and relevant stakeholders highlighting that cold storage monitoring is an important piece of many supply chains.

4. Wireless Data Logger vs USB Data Logger.

Though the primary function of these devices is the ability to track and trace a variety of assets and any violations they may face along the supply chain, it is also equally important to consider the data collection and analysis aspect. There are typically two types of data logger functionalities that exist today, one being wireless cellular data loggers and the other passive USB data logger devices.

Wireless data loggers transmit data to a server which can then be accessed at a later time. Though this is the easiest method, not all companies require a solution with the ability to transfer data in near real-time and receive notifications when violations occur. USB data loggers include a small USB attachment that allows them to be plugged into a system for data to be downloaded.

Whilst this may be a more traditional method, data cannot be retrieved until a journey is completed and a supply chain stakeholder retrieves the USB. It can also lead to data loss if an asset goes missing or is stolen leaving a consignment possibly unable to be relocated.

How To Choose A Data Logger.

When selecting a data logger to be used, various metrics must be analysed to understand what solution best suits a company’s monitoring needs. Adapt Ideations features a wide range of asset tracking and monitoring solutions that can be utilised across a number of industries, including but not limited to cold chain logistics, biopharmaceuticals, and food & beverages.

It is important to identify how long monitoring is required for and the temperature range that is required, to ensure that the solution will meet the requirements of the use case. For example, if the goods being transported are perishables that have to be contained within a specific temperature range in order to remain viable, then temperature tracking is an imperative feature that must be considered when choosing a temperature data logger. In contrast, valuable assets such as fine art may require additional add-on features, such as tamper detection.

Some features are often considered as secondary requirements as they are useful to have but not necessary for every asset being transported. Additional considerations may also include cost, certifications of the solution and security features, validation of devices, scalability of the solutions, ability for vendors to meet requirements, and the ability to integrate via APIs.

How Can I View The Data?

When utilising a data logger to track valuable assets, there are two aspects to consider. While the process of transporting the goods is an important part of the journey, another significant process is data transfer and analysis. Companies often allow the collected data to be viewed through dashboards created by the solution providers or by plugging in USB data loggers for access to file outputs.

Depending on the variation of the data logger, parameter excursions and violations, the trips journey and other vital metrics will be available to view and analyse. Data can allow for business decisions to be backed by data and for trends to be later identified. This ultimately allows operations to be optimised and for continuous improvement to be made across everyday processes such as increased rates of compliance.

What Is The Battery Life Of A Data Logger?

The battery life of a data logger varies depending on the specific device such as sensors integrated and how often the device collects data and the number of daily pings. When selecting a data logger it is important to select one that has a sufficient battery life to last for the required amount of time an asset needs to be monitored. It is important to also consider if assets may experience delays in its journey or if they may sit idle throughout the supply chain. The majority of Adapt Ideations’ next-generation data loggers can last up to thirty days, while some of our solutions have longer battery life.

Enquire to find out more about our innovative solutions and how they can be utilised at enquiries@adaptideations.com

Share Our Post.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.