The Top Benefits Of Adapt Ideations’ Cold Chain Asset Management Solutions

What Are The Main Elements Of Cold Chain Asset Management?

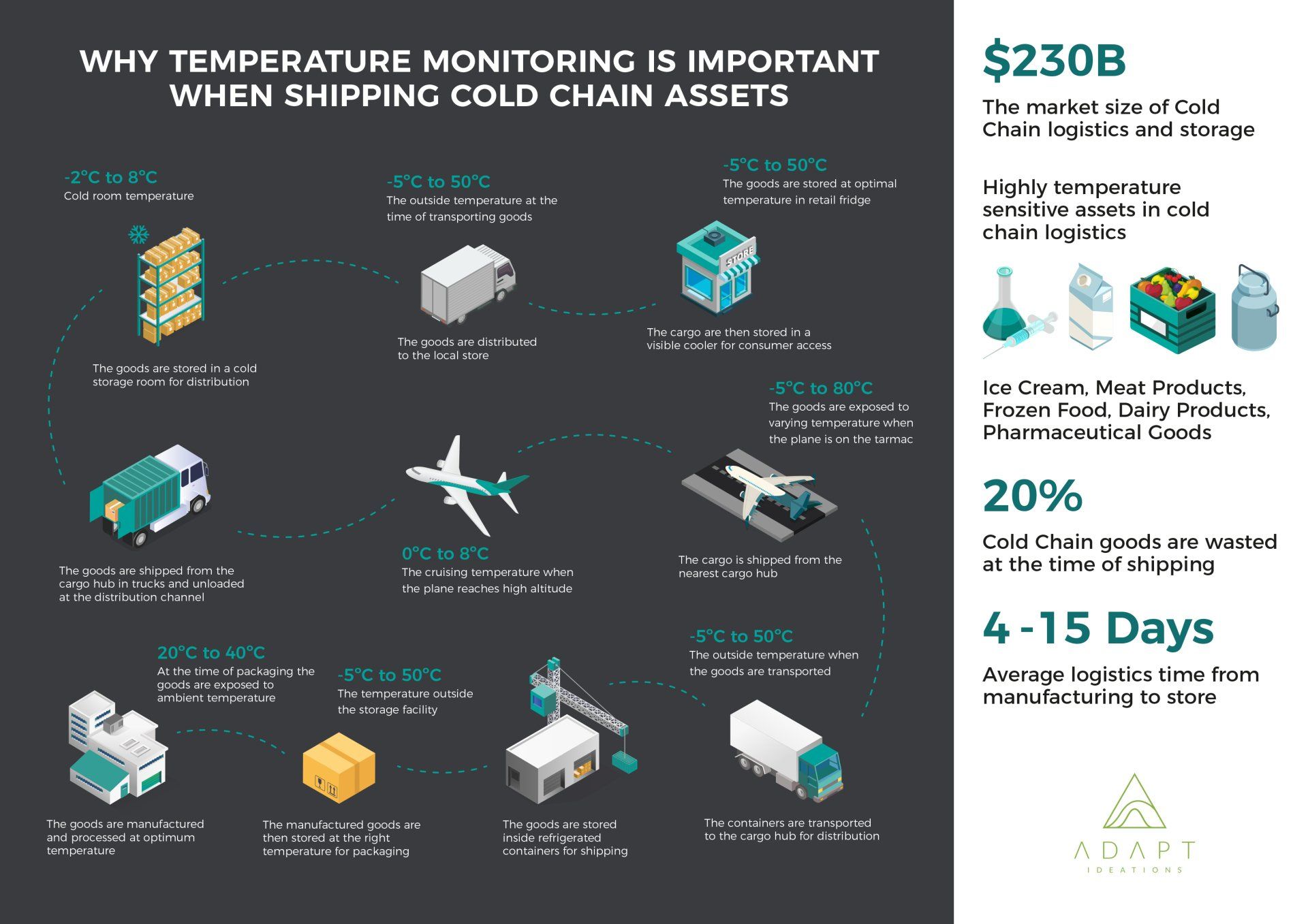

The cold chain can be defined as a temperature-sensitive supply chain including the storage, management, and transportation of perishable goods. Cold chain asset management is a specialised term, primarily referring to the management of perishable goods such as meat, seafood and biopharmaceuticals that are at risk of being spoiled due to temperature fluctuations. Data has a significant role to play in cold chain asset management as the data collected can be further analysed and assist companies in making informed decisions therefore resulting in a greater sense of security, increased quality assurance and a single source of truth for all stakeholders involved in the cold chain.

Perishable products require management throughout the cold chain including manufacturing, transportation between different components of the cold chain, distribution and storage. These types of products need to be constantly monitored in order to avoid damage & wastage of goods or even additional financial expenditure due to losses, delays and reshipment of products. Adapt Ideations specialises in the tracking and monitoring of cold chain assets via our temperature data logger range. The devices are capable of gathering data based on an array of vital metrics, including but not limited to temperature, location, shock, and light exposure. By utilising active asset tracking solutions this can enable companies to collect vital data in near real-time and improve current cold chain asset management processes in place.

Five Benefits Of Utilising Adapt Ideations’ Cold Chain Asset Management Solutions:

Adapt Ideations is heavily involved in supporting the cold chain sector through innovative near real-time temperature data logger devices that have the ability to track and trace a range of metrics whether a shipment is in storage or being transported. Five benefits of utilising our cold chain asset management solutions are outlined below:

1. Wide range of solutions to meet client’s needs:

Adapt Ideations offers a wide range of solutions that fall under 3 primary product families. Our KELVIN & PIXEL temperature data logger suites of devices have an array of features depending on the range and model. The solutions can meet the monitoring needs of various industries and their specific monitoring requirements whether that be the use of single-use, reusable, near real-time or non-connected temperature data loggers. This ensures that each client can utilise a track and trace solution that suits their needs and they do not need to work with multiple vendors if their monitoring needs differ between products.

2. Ability to monitor a range of vital metrics:

Our cold chain asset management solutions have the ability to monitor a variety of vital metrics, such as location, temperature, humidity, shock, and tampering, dependent on the solution in use. Each of these metrics can be useful for clients, especially when the goods in transit are temperature-sensitive, fragile or high-value, as risks such as temperature excursions or potential product damage can easily be monitored and any issues that arise can be quickly rectified.

3. Instant violation notifications:

During the process of tracking vital metrics required for a shipment during transit, it is common for violations to occur whether it is a temperature excursion or even shock. Our KELVIN & PIXEL Suite Of Devices enable users to receive near real-time alerts if violations of set parameters occur. This ultimately enables users to take action to remedy any violations that have occurred. Alerts can also be set up to notify users if the temperature of assets are almost at the set threshold indicating that a violation may soon occur.

4. Simple and user-friendly secured cloud platform:

The data collected by Adapt Ideations devices are directly accessible using our user-friendly secured cloud platform. KELVIN & PIXEL have unique portals, that allow users to view the data collected on all vital metrics, as well as download reports to be utilised for further data analysis and therefore improve on their future cold chain management processes.

5. Readily available technical support:

We offer reliable technical support to our clients and product training where required. We strive to achieve a positive working relationship with our clients by ensuring that their experience with our innovative temperature data logger devices and secured cloud platform is a smooth and simple process.

Adapt Ideations’ Cold Chain Asset Management Solutions:

Here at Adapt Ideations, we are proud innovators of next generation track and trace solutions. Our temperature data logger devices assist in everyday cold chain management collecting vital data no matter where assets are. Get in touch with us today at enquiries@adaptideations.com for further information on our solutions.

Enquire to find out more about our innovative solutions and how they can be utilised at enquiries@adaptideations.com

Share Our Post.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.