Importance Of Food Industry Cold Chain Practices: Why We Need Them

We have done a lot to make our lives more convenient therefore we rely heavily on convenience. In addition to this the food industry is significant to the economy as it can directly affect people's health. A substantial amount of money is spent on purchasing, processing, and transporting food products yet still, a large amount of wastage occurs due to a number of supply chain challenges such as cold chain breaches. All of these combined together highlights the importance of food products and how they are handled.

As per recent studies by United Nations around, "14 percent of all food produced for human consumption is lost before it even reaches consumers." Such wastage can occur for various reasons however some common challenges are unsafe handling, a lack of a proper refrigeration system or breaks within the cold chain.

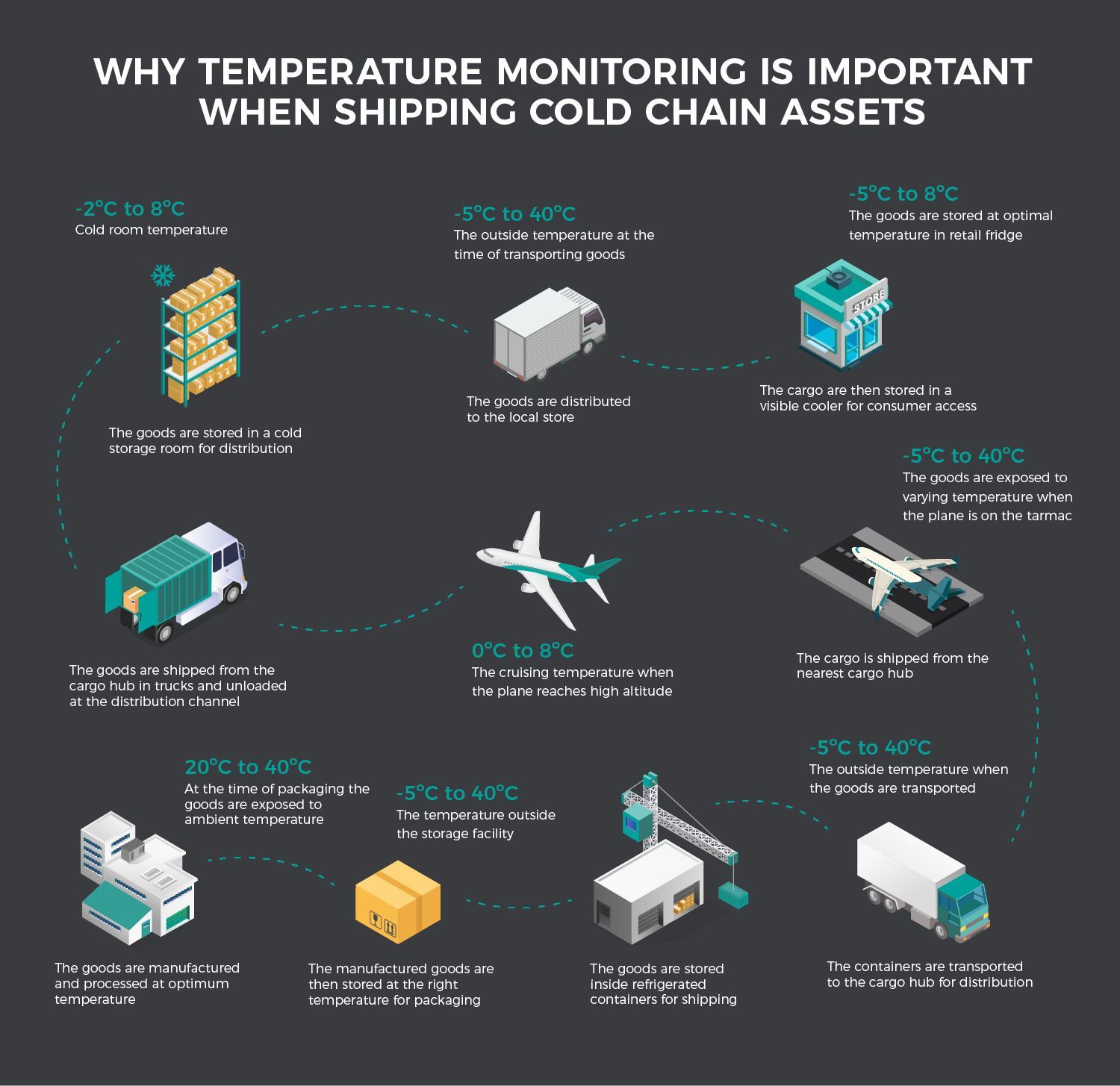

For example, hot-house tomatoes may go through different temperature ranges before reaching end consumers in supermarkets. This demonstrates the complexity of food supply chains as several steps exist within the supply chain, usually handled by different parties for each process. If food products are not kept within the correct temperature ranges this can lead to the product being spoiled leading to higher amounts of food waste. While monitoring of products throughout distribution has a crucial role to play, automated monitoring within facilities is important to help maintain the quality of food products like milk, fruits, vegetables, meat, and fish, whilst in storage.

In this blog, we will discuss how cold chains can impact various challenges of the food industry and how it can become more efficient.

What Is A Cold Chain?

The cold chain is the process of maintaining a temperature-controlled environment for perishable products from the point of production to the point of consumption. The term "food cold chain" refers to a collection of procedures used to ensure that perishable food products are maintained or stored at the ideal temperature range throughout the supply chain, from the moment of harvest to the final consumer at the point of sale.

The global food cold chain market was estimated to be worth $149.43 billion in 2019, of which refrigerated storage is observed to be the fastest-growing segment owing to technological advancements.

Challenges Faced By The Food Industry

The food and beverage sector faces multiple challenges that have an impact on the quality and safety of food items. The following are a few of the major obstacles:

Spoilage & Food Waste

Food waste and spoilage are two of the most significant issues the food sector deals with. It can occur due to various factors, such as inadequate storage, handling, and transportation conditions. Spoilage and food waste not only results in financial losses but can also have negative environmental impacts. According to the Food and Agriculture Organization of the United Nations (FAO), about one-third of the food produced in the world for human consumption is lost or goes to waste every year.

Food Safety Concerns

Food safety is a pressing concern in the food industry. Foodborne infections, which can be severe and even fatal, can be brought on by eating contaminated food products. According to the World Health Organisation (WHO), each year contaminated food causes an estimated 600 million illnesses and 420,000 deaths worldwide. Food safety issues can emerge for a variety of reasons, including inadequate temperature control during storage and transit.

Supply Chain Management

Supply chain management is another significant challenge in the food industry. The food industry's supply chain is complex, involving multiple stakeholders and processes. It can be difficult to manage the supply chain effectively, and any challenges experienced can affect the quality and safety of food products. Ensuring the timely delivery of fresh produce to the end consumer can be a difficult task without effective supply chain management and consistent visibility.

How Can Effective Cold Chain Management Help the Food Industry?

A. Ensuring Food Safety

Temperature Control

Temperature control is a critical aspect of cold chain practices. It involves maintaining the optimal temperature range during storage and transportation to prevent spoilage and maintain food quality. In addition, effective cold chain management helps ensure the safety of food products by maintaining the proper temperature during storage. The risk of contamination can be reduced by keeping the temperature within a certain range as it will also slow down the growth of bacteria and other microbes. Companies who handle cold chain operations can utilise temperature data loggers to help them monitor the temperature of their products in their entire facility.

Reduced Spoilage

Cold chain management can help reduce spoilage by slowing down the rate of food deterioration. It is achieved by maintaining low temperatures, which can prolong the shelf life of food products.

B. Reducing Food Waste

Longer Shelf Life

Effective cold chain management can help reduce food waste by extending the shelf life of food products. Food commodities can stay fresh for longer periods when the right temperature is maintained during storage and transit, minimising the need for disposal due to spoiling.

Preserving Nutritional Value

The nutritional value of food products can also be preserved with the help of cold chains. The loss of nutrients resulting from oxidation and other chemical reactions can be reduced by maintaining the right temperature, ensuring that consumers receive high-quality and nutrient-dense food products.

C. Increasing Operational Efficiency

Improved Inventory Management

By reducing the need for regular inspections and boosting the visibility of inventory levels, cold chains may assist in the improvement of inventory management. It can aid in waste reduction and guarantee that the proper quantity of food items is available when needed.

Optimised Transportation

By ensuring that food products arrive on time and in good condition, cold chain management may also help in the optimisation of transportation. Effective cold chain management can decrease transportation expenses and improve client satisfaction.

To Sum Up

In conclusion, the importance of cold chain practices in the food industry cannot be overstated. Temperature monitoring and control are crucial in ensuring the safety and quality of food products during storage and transportation. To achieve this, temperature data loggers are the best mechanism as they provide real-time monitoring capabilities and alerts in case of any temperature fluctuations.

With real-time monitoring and alert features, Adapt Ideations’ Pixel temperature data loggers are an excellent tool for maintaining the integrity of cold chains and warehouses. Businesses in the food industry must adopt such tools to maintain the integrity of their products and ensure customer satisfaction. By prioritising the implementation of cold chain best practices and utilising advanced monitoring technologies, you can ensure that food products remain safe and fresh from farm to fork.

Enquire to find out more about our innovative solutions and how they can be utilised at enquiries@adaptideations.com

Share Our Post.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.