7 Ways To Increase Sustainability Throughout The Supply Chain

In the past few years, the sustainability of the supply chain has emerged as an essential aspect of corporate operations. In the supply chain framework, sustainability refers to integrating environmentally friendly and socially responsible practices throughout a product's or service's whole lifecycle. Businesses are realising the value of implementing sustainable practices that reduce their environmental impact and support long-term profitability as environmental concerns continue to grow. However, achieving sustainability in the supply chain is not without its challenges. From procurement to transportation and consumer education, various stages require careful consideration and implementation of sustainable strategies.

In this blog post, we will explore various strategies and initiatives that can help increase sustainability throughout the supply chain operations, addressing the challenges faced and showcasing successful case studies.

Understanding The Supply Chain

The supply chain refers to the network of operations involved in producing, distributing, and delivering goods or services. It consists of several processes, including purchasing, manufacturing, transportation, warehousing, and retail. Each stage of the supply chain has the potential to impact the environment through resource consumption, emissions, waste generation, and more. Hence, it is essential to prioritise sustainability throughout the supply chains to mitigate these environmental impacts and achieve long-term viability.

Sustainability in the supply chain refers to the integration of environmental, social, and economic considerations in all stages of the supply chain process. It involves minimising resource consumption, reducing waste generation, and promoting ethical and responsible practices.

Implementing sustainable practices in the supply chain offers several benefits. It enhances a company's reputation, reduces operational costs, improves risk management, improves business operations and helps protect the environment by reducing carbon emissions, conserving resources, and minimising waste. Sustainability should be integrated into each stage of the supply chain. From sustainable sourcing and procurement to green manufacturing, efficient transportation, collaboration, supply chain visibility, and consumer education, sustainable practices contribute to reducing the environmental footprint and enhancing overall social responsibility.

7 Ways To Increase Sustainability Throughout The Supply Chain

Numerous challenges are present in the way of achieving sustainability throughout the supply chain, including lack of awareness, complexity in supplier networks, cost considerations, limited collaboration between stakeholders, and regulatory compliance issues. To counter all these challenges here are seven ways to increase sustainability throughout the supply chain operations.

1. Sustainable Procurement

Sustainable sourcing and procurement involve selecting suppliers and materials that adhere to ethical, social, and environmental standards. By ensuring sustainable supply chain practices, companies can reduce negative environmental and social impacts while promoting responsible business conduct.

For selecting sustainable suppliers and materials, businesses can implement strategies such as conducting comprehensive supplier assessments, considering environmental certifications, prioritising local sourcing, fostering long-term partnerships, and engaging in transparent communication.

Companies like Patagonia and IKEA have demonstrated successful sustainable procurement practices. Patagonia focuses on fair labour practices, using organic materials, and reducing waste. While IKEA sources sustainable wood and promotes responsible forestry practices.

2. Green Manufacturing & Production

Green manufacturing involves implementing environmentally friendly practices in production processes. It aims to minimise energy consumption, reduce emissions, and optimise resource utilisation.

Companies can adopt energy-efficient technologies, such as smart manufacturing systems, and renewable energy sources, to reduce energy consumption and greenhouse gas emissions. Process optimisation and lean manufacturing principles can also contribute to sustainability.

Implementing waste reduction and recycling initiatives is crucial for sustainable manufacturing. Companies can adopt circular economy principles, promote product lifecycle assessments, and encourage the recycling and reusability of materials.

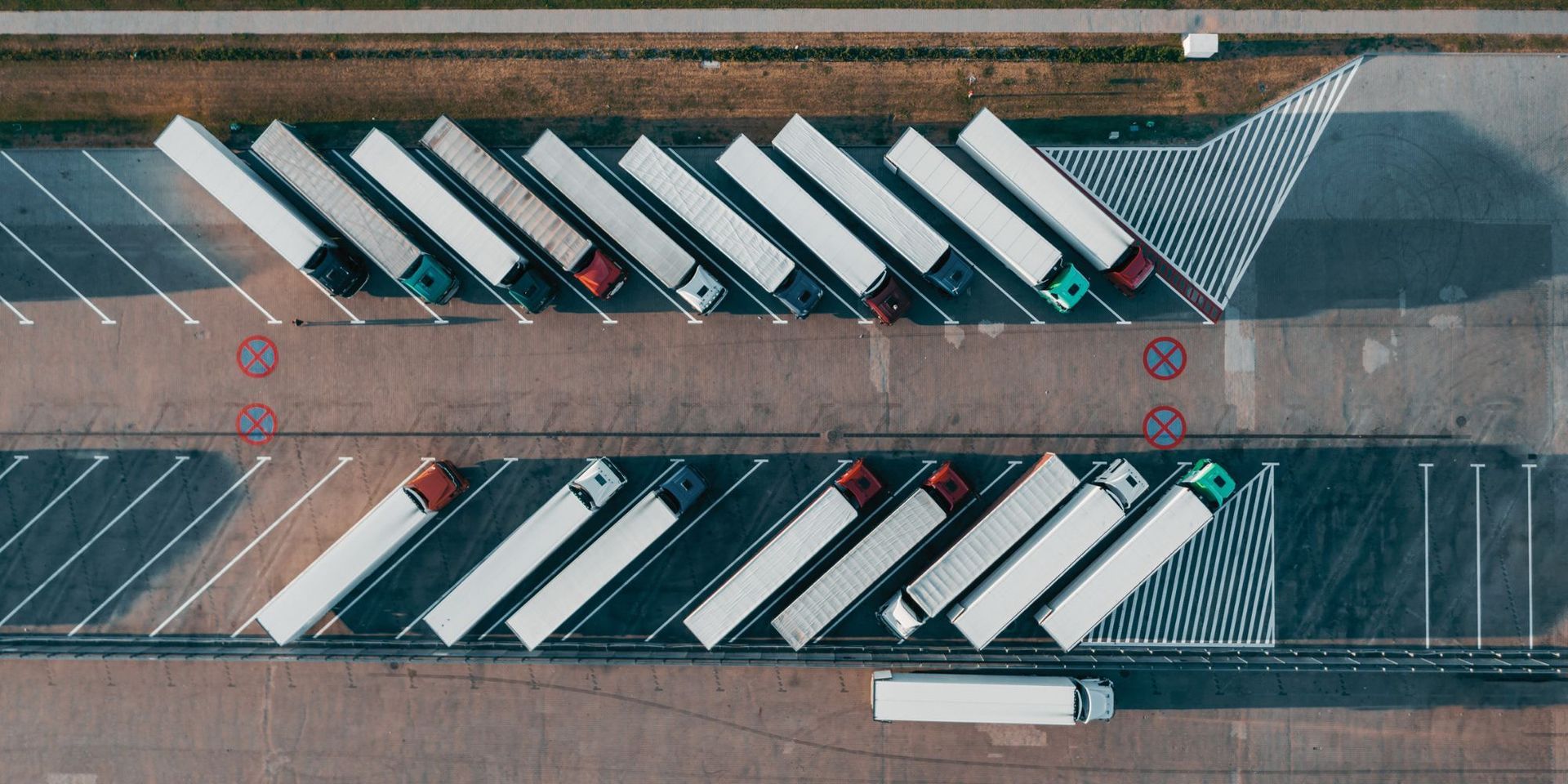

3. Efficient Transportation & Logistics

Transportation and logistics have significant environmental implications, including carbon emissions, air pollution, and congestion. Optimising these processes is crucial for achieving sustainability in the supply chain.

Using route optimisation software and effective transportation planning tactics can help to reduce fuel usage and emissions. Consolidating shipments, using intermodal transportation, and adopting just-in-time inventory management can also reduce environmental impact.

Implementing technologies like GPS tracking, IoT sensors, and real-time monitoring systems like Adapt Ideations’ temperature monitoring solutions can enhance shipment visibility, reduce delays, and optimise logistics operations. These technologies enable efficient route planning, minimise waste, and promote decision-making that can be backed by data.

4. Collaboration & Transparency

Collaboration among supply chain partners is vital for achieving sustainability goals. Companies can cooperate, share best practices, set similar supply chain sustainability goals, and tackle sustainability-related issues as a group.

Supply chain partners can collaborate by sharing sustainability goals, conducting joint audits, and developing common sustainability standards. Sharing best practices and success stories can also inspire others to adopt sustainable practices. Technological tools and platforms, such as blockchain and supply chain management software, can promote transparency by providing visibility into the origin of products, tracking environmental and social metrics, and ensuring compliance with sustainability performance standards.

5. Supply Chain Visibility & Analytics

Supply chain visibility enables organisations to monitor and analyse the environmental impact of their supply chain practicies. It allows for better decision-making, identification of improvement opportunities, and mitigation of risks.

Data analytics can help identify inefficiencies, bottlenecks, and areas of improvement within the supply chain. By analysing data related to energy consumption, waste generation, and emissions, companies can make data-driven decisions to optimise sustainability performance.

Real-time monitoring systems and predictive analytics can provide insights into energy usage, emissions, and waste generation. It enables proactive decision-making, early identification of sustainability risks, and implementation of preventive measures.

6. Communication & Consumer Education

Transparency and effective communication about sustainability efforts are essential for building consumer trust, loyalty and overall customer satisfaction. Companies can utilise various channels, such as websites, social media, and product labelling, to inform consumers about their sustainable practices.

Consumers today are increasingly conscious of sustainability issues and the effects of climate change, and prefer products and brands that align with their values. By offering sustainable products and educating consumers about their benefits, businesses can tap into a growing market, discover new opportunities and gain a competitive advantage.

7. Regulatory Compliance & Certification

Companies must comply with regulations related to carbon emissions, waste management, hazardous substances, and ethical sourcing. Compliance requirements often involve reporting, auditing, and implementing systems to ensure adherence to sustainability criteria.

Certification programs, like LEED (Leadership in Energy and Environmental Design) and Sustainable Forestry Initiative (SFI), validate a company's commitment to sustainability. These programs provide recognition and assurance to stakeholders, fostering trust and credibility.

To Sum Up

Sustainability in the supply chain is essential for mitigating environmental impact, reducing costs, improving reputation, and

meeting consumer demands. It is a critical component of responsible business practices in the 21st century.

Businesses should embrace sustainability throughout their supply chains to drive positive change. By implementing the strategies discussed in this blog post, companies can contribute to a more sustainable future and gain a competitive advantage. To help companies in their journey of achieving greater sustainability, Adapt Ideations can be a great partner which enables real-time monitoring of temperature-sensitive, high-value or critical products. The solutions help companies to understand how products are being handled and stored while collecting vital metrics. This ultimately allows stakeholders to have constant visibility and be able to take necessary action when set parameters are broken allowing waste and spoilage to be reduced.

For further insights and information on sustainability at Adapt Ideations you can visit our sustainability page here.

It is important to remember that sustainable supply chains benefit not just corporations, but also the environment and society as a whole. We can create a better future for future generations if we cooperate and use sustainable practices.

Enquire to find out more about our innovative solutions and how they can be utilised at enquiries@adaptideations.com

Share Our Post.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.