When it comes to

cold storage, humidity monitoring is a critical component of ensuring food and pharmaceutical safety and quality. Without proper monitoring, the products stored in cold storage can quickly become damaged or spoiled due to excess moisture, which can lead to costly losses. This is why accurate monitoring solutions are essential when it comes to

humidity monitoring in cold storage.

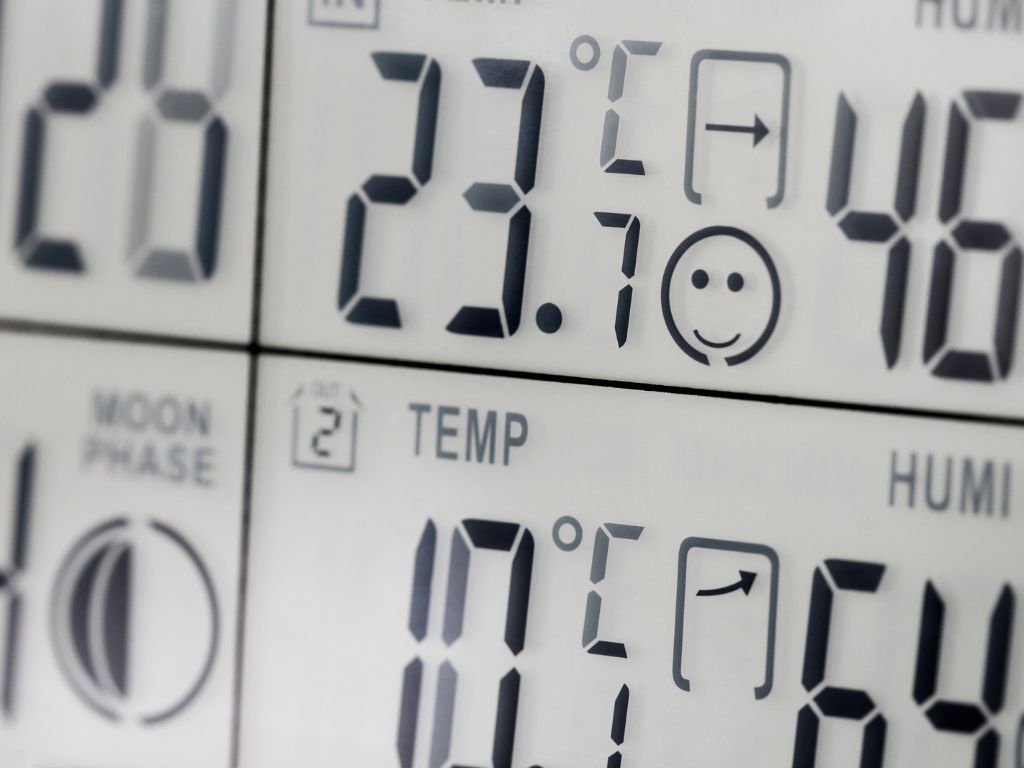

Humidity has a direct impact on the condition of stored goods, especially in low temperature environments. Too much relative humidity (RH) can cause condensation, while too little RH can dry out food and other materials. The optimal levels of RH largely depend on the type of product being stored. As such, it’s important that cold storages are equipped with reliable instruments capable of measuring both temperature and relative humidity.

The most common instrument used for measuring relative humidity is a hygrometer - an electronic device that measures air temperature as well as RH levels. Some hygrometers also come equipped with additional features like alarms or remote monitor capability, which allow users to check the conditions inside their refrigerators from virtually anywhere. Additionally, data loggers are often utilised for long-term measurement and analysis since they provide more accurate readings over extended periods of time than traditional hygrometers do.

In addition to accurate data collection, regular maintenance is essential when it comes to maintaining good quality control in cold storage environments. Regular checks should be done to ensure that all instruments are functioning properly and providing reliable readings; any malfunctions should be addressed promptly before they have a chance to affect the stored items. Additionally, it’s important that all personnel involved in managing cold storages receive appropriate training in order to be able to interpret and act upon collected data correctly.

Due largely to its potential risk factors, humidity monitoring plays a crucial role in cold storage management and should not be taken lightly by facility managers. With proper equipment and regular maintenance procedures in place, facility managers can be rest assured that their stored goods will remain safe from moisture-related damage throughout their shelf-life - resulting not only in improved safety but also cost savings over time.

Humidity Concerns for Pharmaceutical Storage, Data Loggers Are A Vital Tool.

When it comes to storing pharmaceutical goods, humidity monitoring is of utmost importance. Humidity can cause a range of problems, from the degradation of active ingredients in the medication, to increased growth of fungi and bacteria. It can even cause package labels to become unreadable due to condensation build-up. Fortunately, data loggers are used as an effective tool for humidity monitoring when storing pharmaceutical goods.

Data loggers are small devices that measure and record temperature and humidity levels over time. They can be programmed to start recording at specific intervals or on set dates, allowing them to monitor fluctuating conditions in sensitive storage environments. As they offer a wealth of benefits beyond manual measurements and observations, they are commonly used in industries such as food retailing, clinical trials, public health research laboratories and yes – shipping and storage of pharmaceutical goods.

Data loggers come with a range of features depending on the model chosen. These could include alarms in case predetermined thresholds are exceeded; a USB output for easy transfer of data; onboard display screens for quick readings without computer access; LCD backlight for viewing readings in low light conditions; internal memory capacity for storing large amounts of data; rechargeable batteries; Wi-Fi connection capability for remote viewing/accessing recorded data etc.

The use of data loggers provides several advantages when it comes to monitoring humidity levels during the storage of pharmaceutical products. They give you an accurate indication as to whether your required humidity levels have been met or not in any given environment. This can help avoid costly losses due to damaged products caused by incorrect storage conditions or by drug packaging being exposed to excessive moisture. Additionally, since data loggers come with internal memory capacity, they allow data to be stored on the device and ensure data loss does not occur if Wi-Fi or cellular connection is lost. Furthermore, if connected via wireless technology (such as W-Fi), certain models also enable online monitoring from any remote location using tablets etc., providing more real-time control over environmental conditions during transit and storage.

Given their numerous benefits when it comes to ensuring optimal humidity levels during storage of pharmaceutical goods, it’s no surprise that data loggers have become an essential tool in this industry today. By using the right type/model – you can ensure that you remain compliant with all regulations concerning drug stability and shelf-life requirements while also saving yourself from potential losses due to product degradation caused by excess moisture exposure during storage.

Adapt Ideations’ Pixel Data Loggers, Humidity and Temperature Monitoring Solved:

Adapt Ideations’ PIXEL data loggers are one of the leading pieces of hardware in the sector, providing customers with comprehensive monitoring. The loggers are designed to capture temperature and humidity readings in real-time, providing customers with a live condition monitoring of their storage environment.

In addition to accurately measuring current humidity and temperature levels, Adapt Ideations' PIXEL data loggers can also generate events when an adverse change is detected. Should this occur, relevant personnel will be notified to take appropriate action - such as informing supply chain partners of potential issues - while data is stored in the cloud securely and shared if needed.

Moreover, the data collected by the PIXEL data loggers allow stakeholders to identify patterns that may indicate an abnormal change in climate sooner than other types of systems. This provides customers with greater insight into their storage environment, allowing them to act more quickly should any problems arise.

Furthermore, Adapt Ideations’ PIXEL loggers meet government compliance requirements for data collection; ensuring customers remain compliant with local regulations when collecting temperature and humidity readings from their storage environments. In addition, its powerful analytics features allow users to analyse trends over time so they can adjust accordingly if required.

All in all, Adapt Ideations’ PIXEL data loggers provide accurate measurements of temperature and humidity levels at all times; offering enhanced security measures for customer assets stored within these environments whilst keeping them compliant with regulatory requirements regarding data management. Ensuring the safety and quality of temperature-sensitive goods is essential to the preservation of perishable products such as food and biopharmaceuticals. This is why cold chain management is so important, as it helps to extend the lifespan of these goods while maintaining their integrity.

PIXEL W100 is a solution for monitoring temperature and humidity levels in cold storage facilities. It allows users to receive real-time alerts if the set parameters are violated, so that necessary action can be taken immediately in order to reduce potential wastage. With its powerful range of features, PIXEL data loggers are ideal for use in a range of industries including food production, pharmaceuticals, fresh produce, and more.

The device can be used to monitor both temperature and humidity levels with a high degree of accuracy. Temperature sensors measure from -30°C up to +60°C with an accuracy level of ±0.5°C, while humidity sensors measure from 0% up to 99% RH with an accuracy level of ±3.5%. In addition, users can also set up custom thresholds for each sensor in order to receive instant alerts when these parameters are exceeded or violated. Alerts can come via SMS, email or pop-up notifications via the portal so that prompt action can be taken should any problems arise.

The data logger is also incredibly efficient thanks to its long battery life – up to 1 year on a single charge. Furthermore, all data collected by PIXEL is stored on the secured-cloud portal which means users have access anytime anywhere. It also allows multiple users within an organisation to access at once as well as providing integration with other software systems via API.

The PIXEL data loggers are essential in any environment where temperature monitoring is critical. It allows users to continually monitor temperatures and environmental fluctuations, helping to ensure that the environment remains within the optimal temperature range at all times. Overall, PIXEL data loggers are an invaluable tool that helps keep environments operating within the optimal temperature range while providing real-time insights into what’s happening in the environment.

Enquire to find out more about our innovative solutions and how they can be utilised at enquiries@adaptideations.com

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.

Our Guides.

Sign up to our monthly newsletter!

Thank you for signing up.

Please try again later