Shipment Damage Reduction: The Power Of Real-Time Tracking

Maintaining a highly efficient and resilient supply chain is paramount in a world where businesses are racing against the clock to meet customer demands. One of the most daunting challenges faced by companies is the occurrence of shipment damage during transit. The repercussions of damaged shipments extend beyond financial losses, affecting product integrity and customer satisfaction.

In this blog post, we will explore the world of supply chain management and analyse the strategic role of real-time tracking in mitigating shipment damage. You'll learn how real-time tracking helps customers and businesses grow and also ensures safe deliveries.

The Challenges Of Shipment Damage

Shipping goods from point A to point B may seem straightforward, but the complexities of the supply chain introduce various vulnerabilities that can result in shipment damage. The improper handling of products, temperature fluctuations, shocks, and vibrations can compromise the quality and even cause the items to be unusable. A company's reputation and bottom line are directly affected by such occurrences.

When shipments suffer damage, the consequences reverberate through the entire supply chain. The financial implications are significant, encompassing the cost of replacing damaged goods but also the expenses associated with delayed deliveries, potential legal actions, and reputational harm. Brands that fail to safeguard their products risk losing customer trust, and negative word-of-mouth can spread rapidly in the age of social media. Moreover, damaged goods contribute to environmental waste, as resources get wasted on products that never reach their intended recipients.

According to ResearchGate, cargo damage accounts for substantial financial losses across industries, highlighting the pressing need for effective preventive measures. Industry experts and sources emphasise the need for a comprehensive approach to address this challenge. Mitigating shipment damage requires a strategic blend of technology, process optimisation, and a commitment to fostering a culture of accountability throughout the supply chain. As we delve deeper into the role of real-time tracking in the subsequent sections, it becomes evident that solutions are available to help businesses combat these challenges head-on, ensuring that shipments arrive intact, and customers remain satisfied.

The Role Of Real-Time Tracking

Real-time tracking technology is a beacon of innovation within supply chain management as it offers several advantages that reshape how businesses approach logistics. Here's a closer look at the pivotal role it plays:

1. Enhanced Visibility & Insights:

- Real-time tracking provides an uninterrupted stream of data regarding shipment location, condition, and environmental factors.

- Businesses gain a comprehensive view of their supply chain, enabling them to monitor the movement of goods across various touchpoints.

2. Informed Decision Making:

- With real-time data at their fingertips, supply chain managers can make informed decisions promptly.

- Insights into transit delays, route deviations, or potential disruptions empower businesses to take proactive measures and optimise routes.

3. Reduced Response Time:

- The immediacy of real-time tracking minimises the time gap between an issue arising and the corresponding response.

- Businesses can swiftly address any deviations from the expected conditions, preventing the escalation of problems.

4. Risk Mitigation & Management:

- Real-time tracking allows for the identification of potential risks in transit, such as adverse weather conditions or unexpected delays.

- By proactively managing risks, businesses can minimise the likelihood of shipment damage and delays.

5. Supply Chain Transparency:

- Real-time tracking fosters transparency among stakeholders by providing access to real-time shipment data.

- This transparency builds trust between manufacturers, shippers, and customers, enhancing collaboration and communication.

6. Efficient Resource Allocation:

- Data from real-time tracking assists in optimising resource allocation, including labour, fuel, and inventory.

- Businesses can align their resources with actual demand and transit conditions, minimising waste and improving efficiency.

7. Continuous Improvement:

- Real-time tracking data contributes to ongoing process improvement efforts.

- By analysing historical data, businesses can identify trends, patterns, and areas for enhancement within their supply chain operations.

8. Seamless Integration With IoT:

- Real-time tracking technology seamlessly integrates with the Internet of Things (IoT), enabling the monitoring of various parameters, such as temperature, humidity, and shock.

- This integration offers a comprehensive view of shipment conditions, ensuring compliance with quality and safety standards.

9. Competitive Advantage:

- Embracing real-time tracking technology positions businesses as pioneers in their industry, setting them apart from competitors.

- The ability to provide accurate, real-time information to customers enhances their experience and fosters brand loyalty.

10. Future-Proofing Supply Chains:

- As technology continues to advance, real-time tracking is poised to evolve further, offering even more sophisticated insights and capabilities.

- By adopting this technology now, businesses can future proof their supply chains and stay ahead of the curve.

By integrating real-time tracking into supply chain operations, businesses embrace a new era of agile, responsive, and damage-resistant logistics. This technology doesn't merely bridge gaps. It transforms the entire landscape, paving the way for safer, more efficient shipments.

Maintaining Product Integrity Through Real-Time Monitoring

Real-time tracking does more than provide visibility; it safeguards product integrity throughout the shipping process. Through real-time monitoring, businesses can detect potential issues such as temperature fluctuations, shocks, and vibrations that could compromise the quality of the goods. This level of monitoring ensures that products arrive in the same condition they left the manufacturer, preserving their value and utility.

Boosting Customer Satisfaction & Beyond

Preventing shipment damage goes hand in hand with enhancing customer satisfaction. The correlation is clear: Undamaged products lead to happy customers. Satisfied customers, in turn, foster brand loyalty and contribute to business growth. A report by

Purolator International points out that minimising damage risk not only protects shipments, but also protects brand reputation. By demonstrating a commitment to delivering pristine products, businesses can differentiate themselves in a competitive marketplace and secure long-lasting customer relationships.

Compliance Requirements & Regulatory Standards

1. Safety & Compliance Assurance:

- Real-time tracking technology is critical in meeting compliance requirements and adhering to industry regulations.

- Monitoring temperature-sensitive shipments in real-time ensures that products are transported within specified temperature ranges, avoiding regulatory violations.

2. Proof Of Adherence:

- Accurate and continuous data from real-time tracking serves as evidence of compliance during audits and inspections.

- Businesses can showcase their commitment to quality and safety by providing documented records of shipment conditions.

3. Minimised Legal & Financial Risks:

- Real-time tracking mitigates the risk of penalties, fines, or legal actions resulting from non-compliance.

- By adhering to regulatory standards, businesses safeguard their reputation and financial well-being.

Instant Alerts & Timely Precautionary Measures

1. Early Warning System:

- Deviations from pre-determined conditions trigger instant alerts, enabling immediate attention to potential issues.

- Supply chain managers and relevant stakeholders receive real-time notifications, allowing them to take swift action.

2. Proactive Response Mechanism:

- Real-time tracking empowers businesses to address problems before they escalate into significant damage or losses.

- Precautionary measures can be taken in real-time, including re-routing shipments, adjusting temperature controls, or re-securing packaging.

3. Agility and Responsiveness:

- Timely interventions enabled by real-time tracking showcase the agility and responsiveness of modern supply chain management.

- Businesses can swiftly adapt to changing circumstances, minimising disruptions and maintaining customer satisfaction.

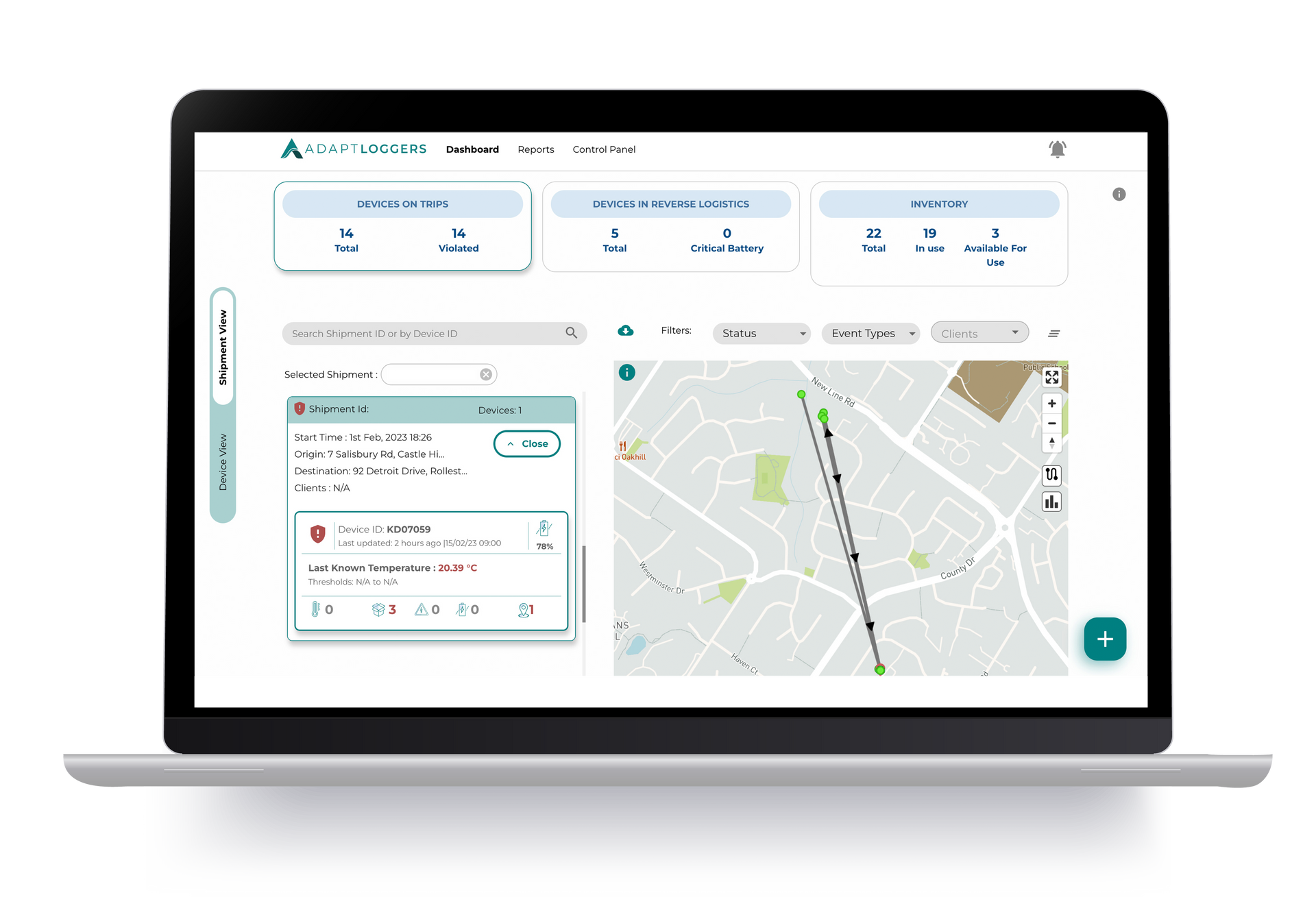

Introducing Adapt Ideations' Solution: IoT Temperature Data Loggers

Now that we've explored the benefits of real-time tracking, allow us to introduce a solution that embodies these principles—Adapt Ideations' IoT temperature data loggers. These innovative devices take real-time tracking to the next level, specifically designed to monitor temperature-sensitive shipments. With Adapt Ideations' KELVIN solution range, you can keep an eye on your goods in real-time, ensuring they remain within the required temperature range. Should any deviations occur, you'll receive an instant alert, enabling you to take swift precautionary measures and maintain the integrity of your shipments.

These sophisticated devices seamlessly integrate with your supply chain, offering unparalleled insights into the conditions your shipments experience. The KELVIN solution range isn't just a tool; it's a partner that ensures your products remain in optimal conditions, even amidst the most challenging transit scenarios.

Don't just track your shipments; elevate them to a new level of security and precision with Adapt Ideations' KELVIN IoT enabled temperature data loggers.

Explore Adapt Ideations’ KELVIN IoT Temperature Data Loggers

Enquire to find out more about our innovative solutions and how they can be utilised at enquiries@adaptideations.com

Share Our Post.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.