Enhancing Business Operations with Real-Time Visibility Solutions

Managing perishable goods in the Australian and New Zealand (ANZ) market presents unique challenges. The demand for

perishable products, such as food and beverages, is on the rise due to a range of factors. In 2023, the

food market in ANZ is estimated to reach US$87.66 billion, with meat being the largest segment, accounting for US$17.84 billion. This growth is a testament to the importance of this sector in the region.

The key to success lies in effectively managing the supply chain of perishable goods, such as food and beverages. Any lapse in monitoring these products can result in losses, compliance issues, and supply chain inefficiencies. This blog explores how real-time visibility solutions can be a game-changer for companies dealing with perishable goods in the ANZ region.

The Significance of Real-Time Visibility in Cold Chain Technology

Real-time visibility solutions are the game-changer in this scenario. By providing businesses with immediate insights into the conditions of their perishable goods, real-time visibility solutions help prevent temperature and other deviations of set conditions that can lead to spoilage. When you know where your goods are and their condition, you can make smarter decisions backed by data.

In essence, they ensure that your cargo reaches its destination in optimal condition, satisfying both consumers and regulators. The need for these solutions has never been more apparent, especially with the perishable prepared food market expected to reach $120.5 billion in 2023.

It's not just about efficiency. Real-time visibility can make your cold chain logistics more environmentally friendly.

Challenges in Perishable Goods Management

The challenges in managing perishable goods are multifaceted. It involves a web of logistical operations, compliance with stringent standards, and the need to achieve sustainability goals. Let's dive into these challenges:

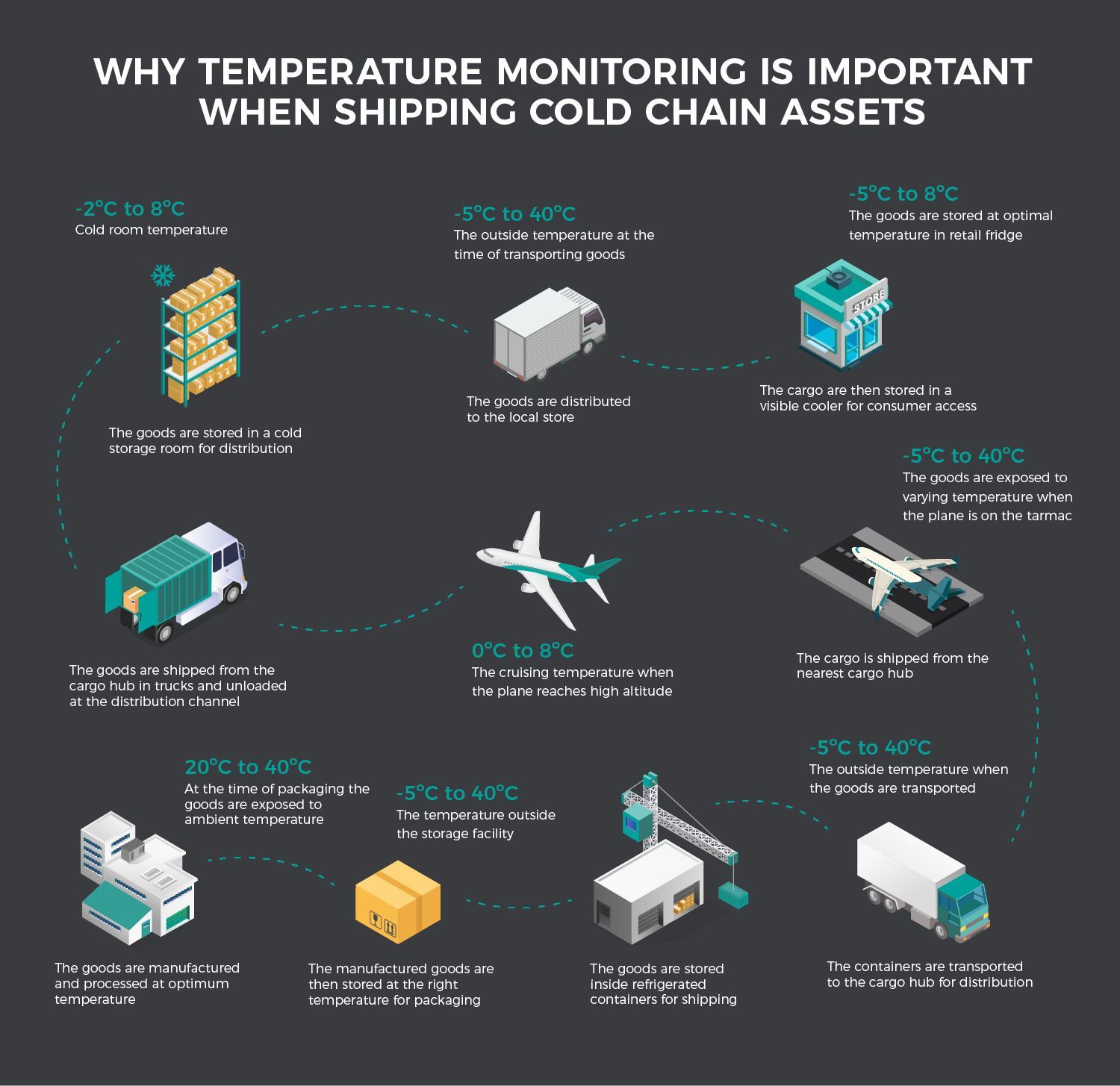

- Logistical Complexities: Perishable goods require temperature-controlled environments throughout their journey. The complexities of maintaining these conditions are not to be underestimated.

- Compliance Requirements: Regulatory bodies demand strict adherence to temperature and humidity standards to ensure the safety and quality of perishable goods. Non-compliance can result in legal consequences and damage to your brand reputation.

- Sustainability Imperative: Modern businesses are focusing on sustainability. Implementing eco-friendly and energy-efficient practices is essential in perishable goods management.

Benefits of Real-Time Monitoring Solutions

Solutions enabling real-time visibility can provide a range of benefits, including:

- Immediate Alerts: Real-time visibility solutions offer alerts when conditions deviate from the specified range. It will allow you to take prompt action and prevent spoilage.

- Data-Driven Decision Making: With access to real-time data, businesses can make informed decisions, optimise routes, and enhance supply chain efficiency.

- Customer Satisfaction: Consistently delivering high-quality products to customers fosters trust and satisfaction, leading to long-term relationships.

- Optimised Routes: Real-time monitoring solutions help to choose the most efficient routes, minimising transit time and costs.

- Reduction in Waste: Minimising spoilage reduces waste and in turn, helps in achieving sustainability goals.

- Simplified Compliance: Meeting regulatory requirements becomes easier with detailed records of temperature and other vital conditions.

- Proactive Compliance: By having access to real-time data on vital conditions that products are exposed to, businesses can simplify their understanding of compliance for every stakeholder and demonstrate their commitment to regulatory compliance.

Read more about - The Importance Of Supply Chain Visibility For Perishable Goods.

Real-Time Visibility Solutions for Perishable Goods in ANZ

The current market trends in the ANZ region necessitate a proactive approach to perishable goods management. As the largest segment in the food market in 2023 is meat, there's a growing need for reliable visibility solutions to protect these goods and understand how they are handled.

How Cold Chain Logistics Impact Perishable Goods

Cold chain logistics are the backbone of managing perishable goods. Real-time visibility solutions ensure that these products remain in optimal condition. Starting from the moment they leave the manufacturer to their final destination.

Solutions for Enhanced Visibility in the Supply Chain

We at Adapt Ideations provide a solution that aligns perfectly with the needs of the industry. We offer two innovative real-time monitoring solutions:

- KELVIN IoT Devices: These keep an eye on your temperature-sensitive shipments, ensuring they always remain compliant. The solution ensures visibility throughout the supply chain, reducing the risk of spoilage and damage.

- PIXEL Temperature Data Loggers: Made for cold storage monitoring they help you ensure perishable goods have been stored within the correct conditions ultimately ensuring compliance has been maintained and any waste of products is reduced.

Addressing Challenges & Achieving Efficiency

Real-Time Monitoring with KELVIN IoT Devices.

Our KELVIN IoT Track-and-Trace Devices offer real-time monitoring, with the following advantages:

- Immediate Alerts: Receive instant notifications of temperature and other deviations on vital conditions, ensuring rapid response.

- Data Analytics: Access data any time anywhere alongside reporting capabilities with the portal to make informed decisions and optimise processes.

- Sustainability Focus: Our devices are reusable, promoting the concept of greener cold chains and eco-friendly practices.

Utilising PIXEL Temperature Data Loggers for Cold Storage Operations.

The PIXEL Temperature Data Loggers are tailor-made for cold storage operations:

- Real-Time Visibility: Keep an eye on temperature and humidity conditions within your cold storage spaces in real-time, ensuring the quality and safety of your goods.

- Efficiency & Compliance: Achieve greater efficiency and compliance standards for cold storage operations.

Advantages of Complete Visibility in the Supply Chain

Complete visibility across the supply chain is not just an advantage but a necessity. It:

- Prevents Losses: Immediate alerts help prevent losses due to spoilage or non-compliance.

- Enhances Reputation: Delivering top-quality products consistently enhances your brand's reputation.

- Boosts Sustainability: By reducing waste, your business contributes to a greener future.

Conclusion: The Power of Real-Time Monitoring for Perishable Goods

In conclusion, the demand for perishable goods in the ANZ market is on the rise, and businesses need to adapt to this growing market. Real-time visibility solutions are the key to optimising perishable goods management in the ANZ market. Also, the exponential growth of the perishable prepared food market emphasises the need for immediate action. It's time to revolutionise your cold chain and logistics operations with Adapt Ideations' KELVIN IoT Devices and PIXEL Temperature Data Loggers.

Ready to ensure the success of your perishable goods in the ANZ market?

Contact us today to find the perfect solution that aligns with your business's needs.

The main challenges include maintaining temperature-controlled logistics, meeting stringent compliance standards, and achieving sustainability goals.

Real-time visibility solutions provide immediate alerts for temperature and humidity deviations, leading to more efficient supply chain operations, improved compliance, and a stronger focus on sustainability.

KELVIN IoT Devices offer immediate alerts, access to real-time data and reports, and a focus on sustainability due to their reusability, promoting eco-friendly cold chains.

PIXEL Temperature Data Loggers offer automated monitoring of temperature and humidity conditions within cold storage facilities, helping businesses achieve compliance with standards, and reduce waste and damage of products due to non-compliance.

Enquire to find out more about our innovative solutions and how they can be utilised at enquiries@adaptideations.com

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.

Our Guides.

Sign up to our monthly newsletter!

Thank you for signing up.

Please try again later