Ensuring Seamless Cold Chain Transportation: 5 Key Strategies For Effective Risk Mitigation

The world of logistics is a complex web of interconnected systems. At the heart of it lies the cold chain. Picture a convoy of products, ranging from pharmaceuticals and perishable food items to chemicals and vaccines, making their way across the globe with one crucial requirement, maintaining temperature integrity throughout the supply chain. In this blog, we'll dive into the importance of seamless cold chain transportation, explore the risks and challenges involved, and present five key strategies for effective risk mitigation.

Understanding Cold Chain Transportation

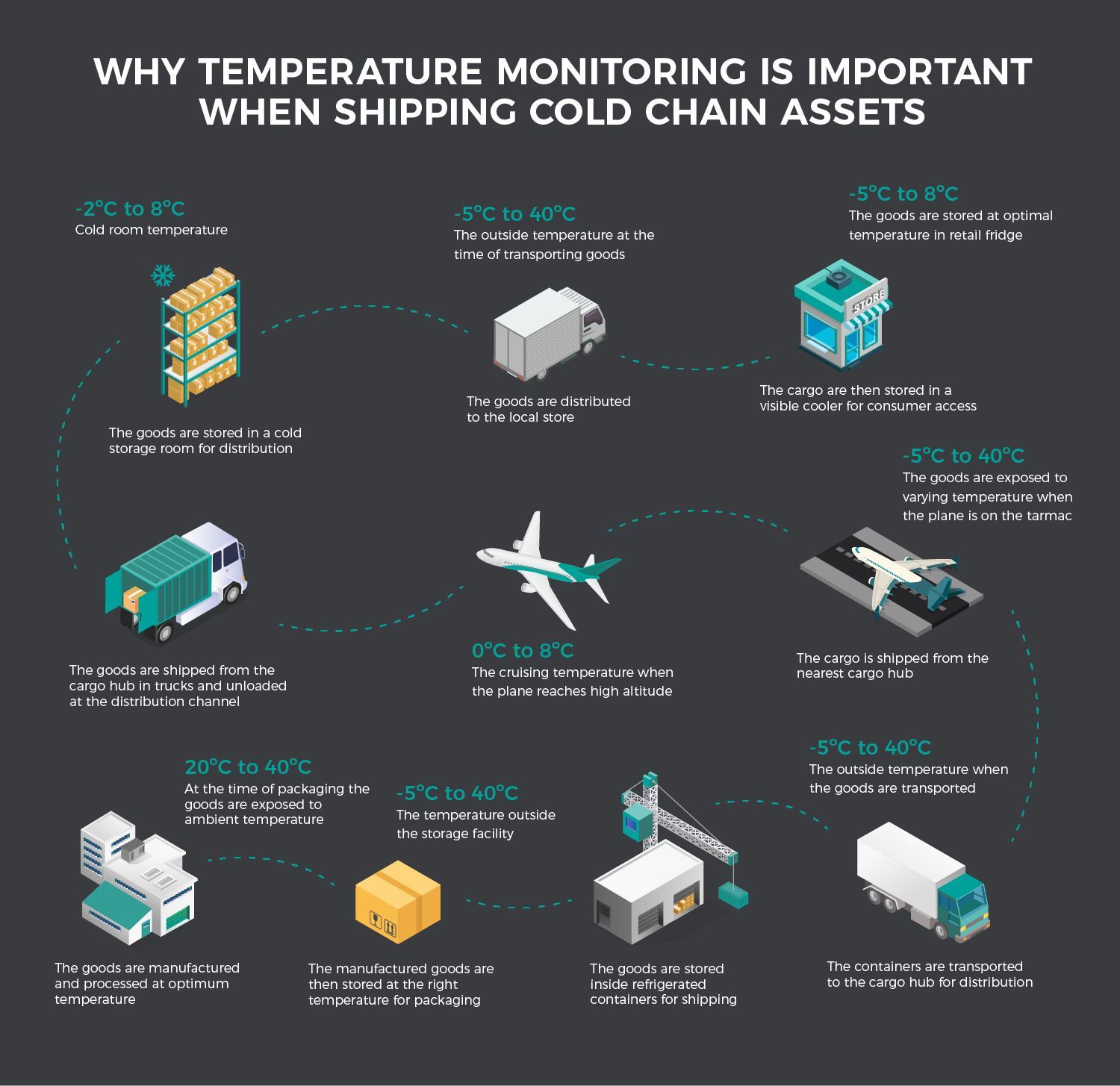

Keeping perishable commodities in a consistent temperature range from production to consumption is called the "cold chain”. It includes many interrelated elements, including storage facilities, refrigerated vehicles, and temperature monitoring devices. The process of transporting temperature-sensitive goods from one location to another while preserving the required temperature range is known as "cold chain transportation”. It includes several elements, such as cold storage facilities, temperature-controlled vehicles, and specialised packaging.

To guarantee product quality and safety, sectors like life sciences, food & beverages, and chemicals largely rely on cold chain logistics. These sectors depend on maintaining precise temperature conditions to preserve product quality, safety, and efficacy. Prominent stakeholders in the cold chain process include manufacturers, logistics providers, distributors, and retailers. Each stakeholder plays a crucial role in ensuring the integrity of the cold chain, from initial production to final delivery.

Common Risks & Challenges In Cold Chain Transportation

Temperature excursions, equipment failures, regulatory compliance, and data management are among the hurdles that should be effectively addressed for a seamless cold chain. Even slight temperature variations can undermine a product's effectiveness, safety, and consumer trust. Such breaches of set conditions can also have a disastrous financial impact and impact a company's reputation. Let's talk about common risks and challenges encountered in cold chain transportation:

- Temperature excursions pose a significant risk to product quality and safety. In a 2019 report by IQVIA Institute for Human Data Science, the biopharma industry loses around $35 billion annually because of temperature excursions and failures. Temperature fluctuations can cause valuable commodities to decay, lose their effectiveness, or even be lost entirely whether because of inadequate refrigeration or unforeseeable events during transportation.

- Equipment failures and maintenance issues can disrupt the cold chain, causing temperature deviations and compromising product integrity. Regular inspection, maintenance, and calibration of refrigeration units and temperature monitoring devices are essential to prevent such failures.

- Regulatory compliance and quality control are crucial aspects of cold chain transportation. Adherence to industry regulations and guidelines ensures that products meet the required standards for safety and efficacy.

- In order to collect and analyse temperature data along the entire cold chain, data management and monitoring obstacles must be overcome. It requires real-time monitoring, data recording, and correct interpretation of data to identify potential problems and take corrective action as soon as possible.

Importance Of Effective Risk Mitigation

1. Financial & Reputational Risks

Cold chain failures can lead to significant financial losses, including product spoilage, wasted inventory, and potential lawsuits. Moreover, companies risk damaging their reputation and losing consumer trust, which takes years to rebuild.

2. Impact On Product Quality, Safety, & Consumer Trust

Consumers rely on the cold chain to deliver safe and high-quality products. A breakdown in the cold chain can compromise the efficacy of medications and the freshness of food and also the overall safety of the products, eroding consumer confidence.

3. Legal & Regulatory Consequences

Non-compliance with cold chain regulations can result in legal consequences, including fines, product recalls, and even license revocations. Adhering to the standards and guidelines is essential to avoid legal consequences and maintain business continuity.

4. Cost Saving Opportunities

Effective risk mitigation strategies not only prevent losses but also present opportunities for cost savings. By optimising the cold chain process, companies can minimise waste, improve efficiency, and reduce operational expenses.

5 Key Strategies For Effective Risk Mitigation & Ensuring Seamless Cold Chain Transportation

1. Implementing A Comprehensive Cold Chain Monitoring System

Businesses must embrace advanced technology solutions to cope with the cold chain's complexities. Adapt Ideations’ IoT temperature monitoring solutions alongside our SEA partner Intellistride can revolutionise the cold chain process and offer a comprehensive approach to cold chain monitoring.

The product’s advanced features, such as real-time location and temperature monitoring, shock and tampering detection, cloud-based platform, alongside the data collected, provides actionable insights into temperature conditions throughout the supply chain further, enabling proactive risk management.

2. Ensuring Proper Temperature Management

Setting temperature thresholds and alarms is crucial to maintaining the integrity of temperature-sensitive products. Continuously tracking temperature data in real-time is beneficial, and acting swiftly to mitigate temperature excursions is essential for maintaining the integrity of the cold chain.

With Intellistride & Adapt Ideations’ IoT solutions, businesses can establish customised temperature parameters and receive instant alerts in case of deviations. Real-time monitoring and recording of temperature data allows for proactive decision-making to mitigate risks promptly.

3. Robust Equipment Maintenance & Calibration Practices

Regular inspection and maintenance of temperature monitoring equipment is vital for accurate readings. Regular inspection schedules, maintenance chores, and temperature monitoring equipment validation is critical for minimising unexpected failures and guaranteeing accurate temperature data.

4. Compliance With Regulatory Standards & Quality Control Measures

Meeting regulatory standards and adhering to quality control measures is essential for cold chain transportation. Familiarising yourself with relevant regulations and guidelines, such as Good Distribution Practice (GDP) for pharmaceutical products, helps ensure compliance. Implementing standard operating procedures (SOPs) tailored to your specific operations guarantees consistent quality and reduces risks.

5. Ongoing Training & Education of Personnel

Human error can often be a significant factor in cold chain disruptions. Providing proper ongoing training and education to personnel involved in the cold chain process is essential for effective risk mitigation. Businesses can promote a culture of excellence and continuous improvement by adhering to protocols and best practices. Knowledge sharing initiatives further enhance the collective expertise of the workforce involved in the cold chain process.

To Sum Up

In the world of cold chain transportation, effective risk mitigation is not a luxury—it's a necessity. By understanding the risks, implementing advanced technologies like our

IoT temperature monitoring solutions in conjunction with our SEA partner

Intellistride, and adopting key strategies, businesses can safeguard product quality, maintain consumer trust, and thrive in a competitive market.

To explore how Adapt Ideations’ IoT temperature monitoring solutions alongside their SEA partner Intellistride can enhance your cold chain transportation, visit here. Our team is ready to provide further information, schedule product demonstrations, and address any inquiries you may have. Don't compromise on the safety and quality of your temperature-sensitive products—select Intellistride and Adapt Ideations for all your track and trace needs for a seamless monitoring experience throughout cold chain transportation.

Enquire to find out more about our innovative solutions and how they can be utilised at enquiries@adaptideations.com

Share Our Post.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.